Institute of Polymer Engineering

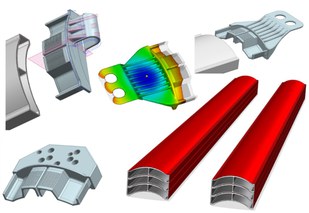

We create sustainable, plastic-based product and processes innovations with a focus on high-performance polymers and composites.

We achieve the level of ingenuity required for this by implementing an interdisciplinary approach, fusing together the fields of raw materials, construction and processing. In doing so we approach product development with plastics in a holistic way.

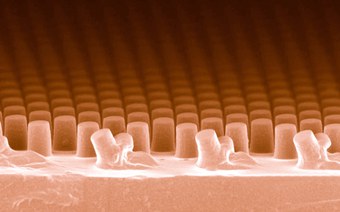

Our expertise in the fields of chemistry and analytics, process engineering and structural mechanics blends very well with the surface structuring and functionalisation expertise of the FHNW Institute of Polymer Nanotechnology.

Selected Projects

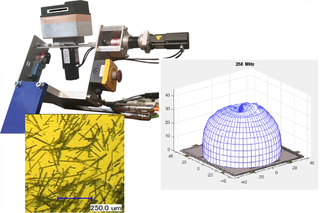

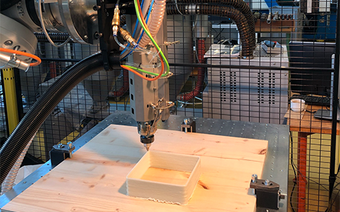

Robot-Assisted Additive Manufacturing

Robot-assisted additive manufacturing is a relatively novel but promising technology for economically producing even larger plastic components.

to Robot-Assisted Additive Manufacturing

Digitization of the temperature control unit

Innovative, model-based thermal industrial systems: Tool Temp AG and three institutes of engineering at the FHNW realized a novel control technology concept.

to Digitization of the temperature control unit

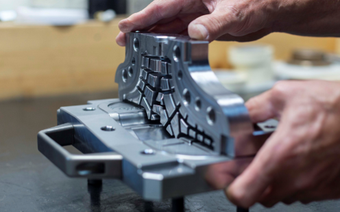

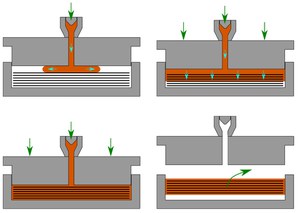

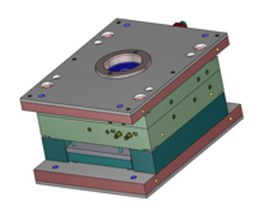

Integrated RFID tags in polymer injection molding

For the traceability of plastic components, if at all, they are marked with a simple code. The current methods for these codes are complex and do not offer the ...

to Integrated RFID tags in polymer injection molding

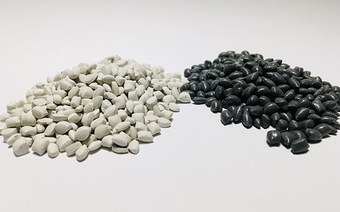

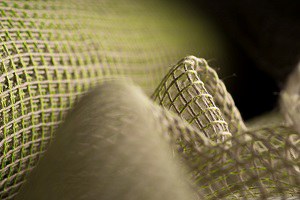

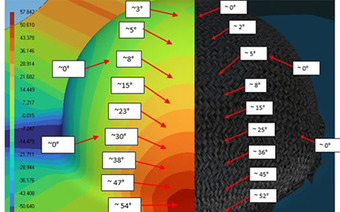

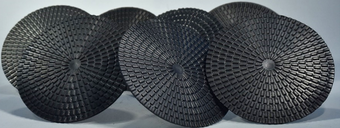

Consolidation of hybrid textiles

We develop and validate a consolidation model for the production of composites based on hybrid textiles. These consist of plies of reinforcing woven fibres and ...

to Consolidation of hybrid textiles

Infrastructure

Analysis of material properties and their effects

Infrastructure