High-phi-factor calorimetry

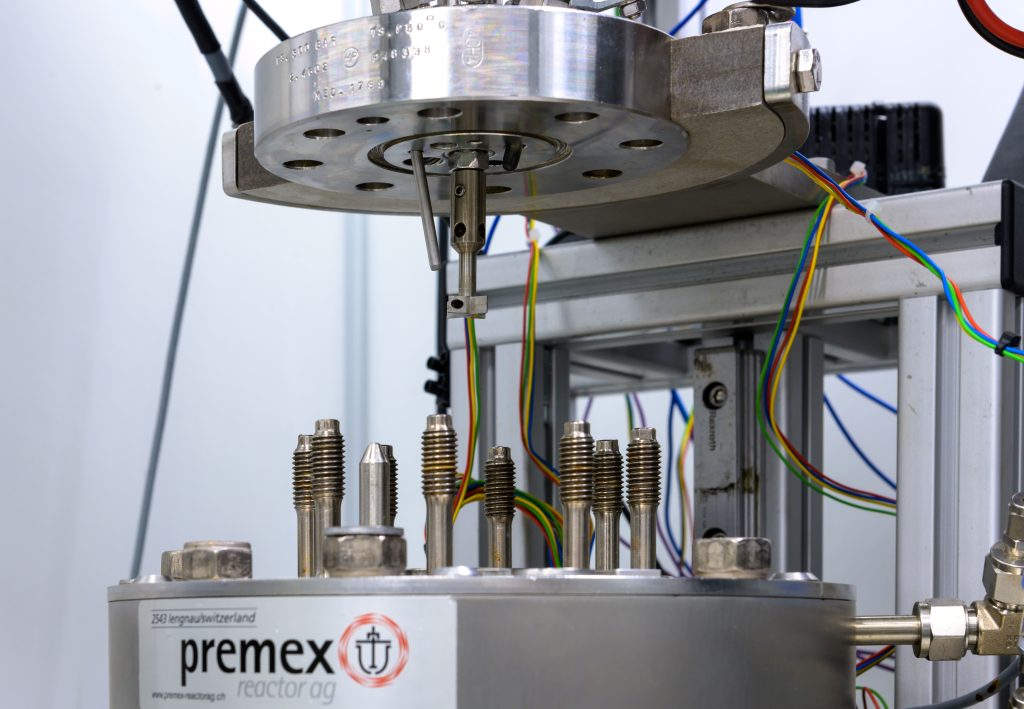

Located on three floors in the PTC, our chemical pilot plant provides companies with an ideal testing environment. Specifically, for assessing the thermal process safety of hazardous reactions, we have a «hig-phi-factor» reaction calorimeter that allows the validation of reaction models under agitated conditions.

Application example: Polymerization of vinyl-acetate

TThe study was carried out in our «high-phi-factor» calorimeter. After initial DSC measurements the polymerization of vinyl acetate was investigated under non isothermal conditions: The educts were loaded into the autoclave at room temperature. Afterwards the reaction mass was heated similar to a DSC with temperature ramps of 1 … 4 K/min up to 200 °C. During the temperature ramp the reaction mass was continuously agitated. This allows the investigation of the reaction under more realistic conditions compared to e.g. non-agitated DSC or ARC measurements only. Based on the measured temperature and pressure profiles it is possible to validate reactor models describing the kinetics as well as the vapor liquid equilibrium of the reactive system as a function of conversion. The methodology shown here could be used to establish reactor models for the conversion of batch process to continuous processes.