Stepping up 3D printing of orthopaedic insoles

Daniel Seiler’s lab is revolutionizing how personalised orthopedic insoles are made

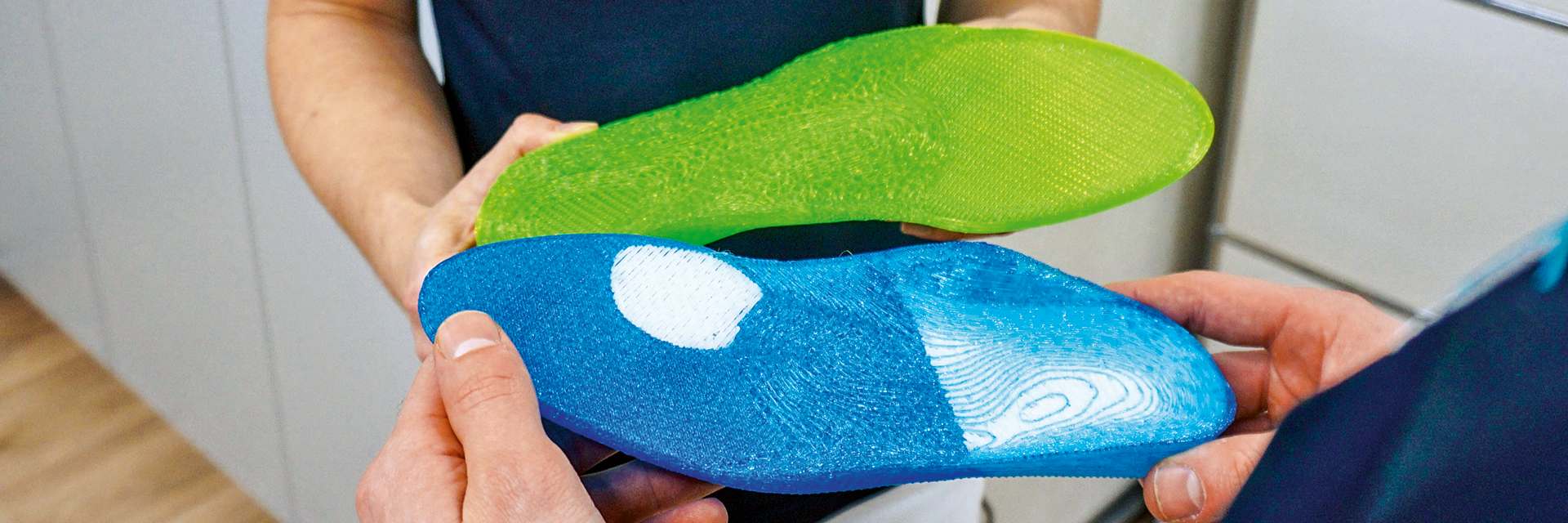

Orthopaedic insoles help redistribute pressure and relieve sensitive areas of the feet, making it more comfortable for people with foot misalignments to walk and perform daily activities. Orthopaedic insoles are also a crucial tool for patients whose foot nerves have lost sensitivity, which can unknowingly lead to pressure sores or even amputation. In non-medical applications, insoles can help increase comfort and stability for adults, offer support to people who spend a lot of time working on their feet, and boost performance in running and other sports.

Even to this day, personalised insoles are primarily produced using computer numerical control (CNC) machines and are fine-tuned manually. This traditional method of milling insoles is not only energy-intensive but also generates a substantial amount of noise, dust and chip waste. The shift toward 3D printing of personalised insoles can reduce waste by 95%. However, the key challenge is the printer’s ability to manage several types of materials with different hardness levels and properties.

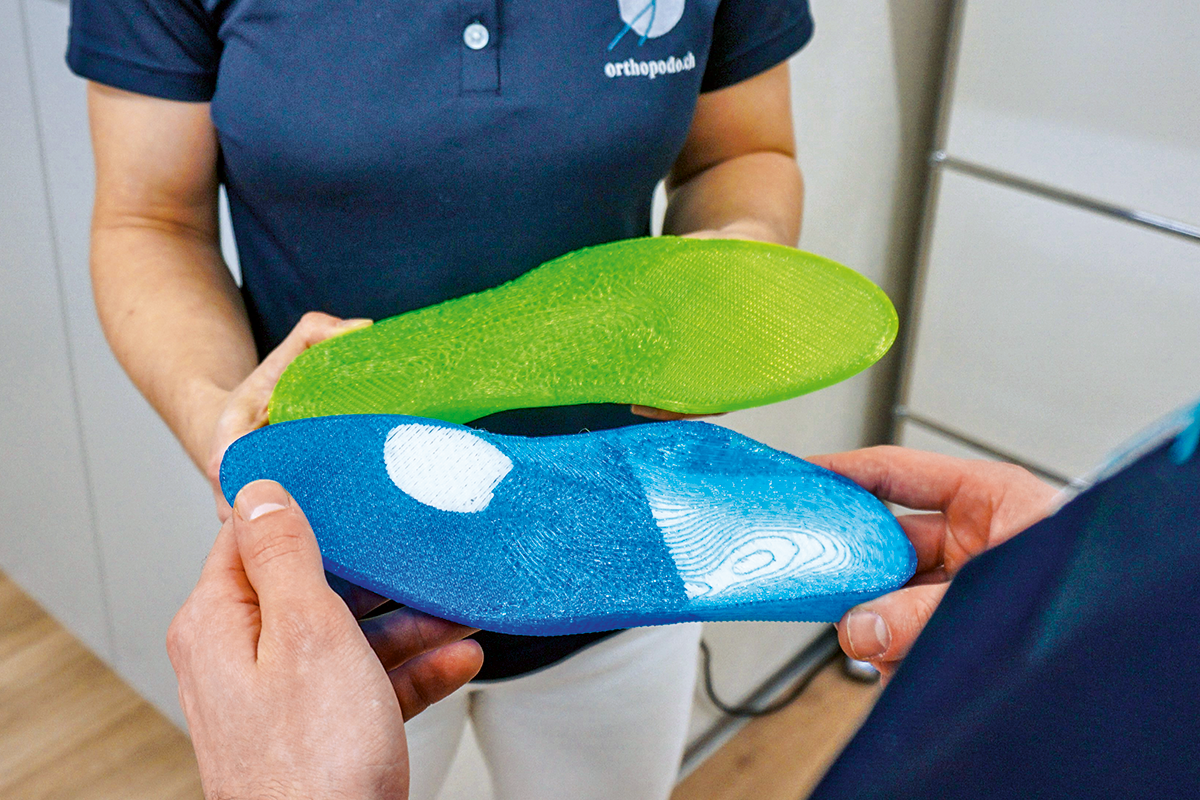

In an Innosuisse project performed in collaboration with the company Orthopodo Malgaroli, Daniel Seiler’s lab at the Institute for Medical Engineering and Medical Informatics has developed an automated digital production process process for 3D printing of personalised orthopaedic insoles.

“Orthopodo Malgaroli approached us with a desire to make their production process more digital, efficient and sustainable” says Seiler. “This involves not only a shift toward 3D printing processes, but also new methods in scanning patients’ feet and arriving at the optimal insole design. We envision an end-to-end solution from foot scanning to insole output that can revolutionise how personalised insoles are made.”

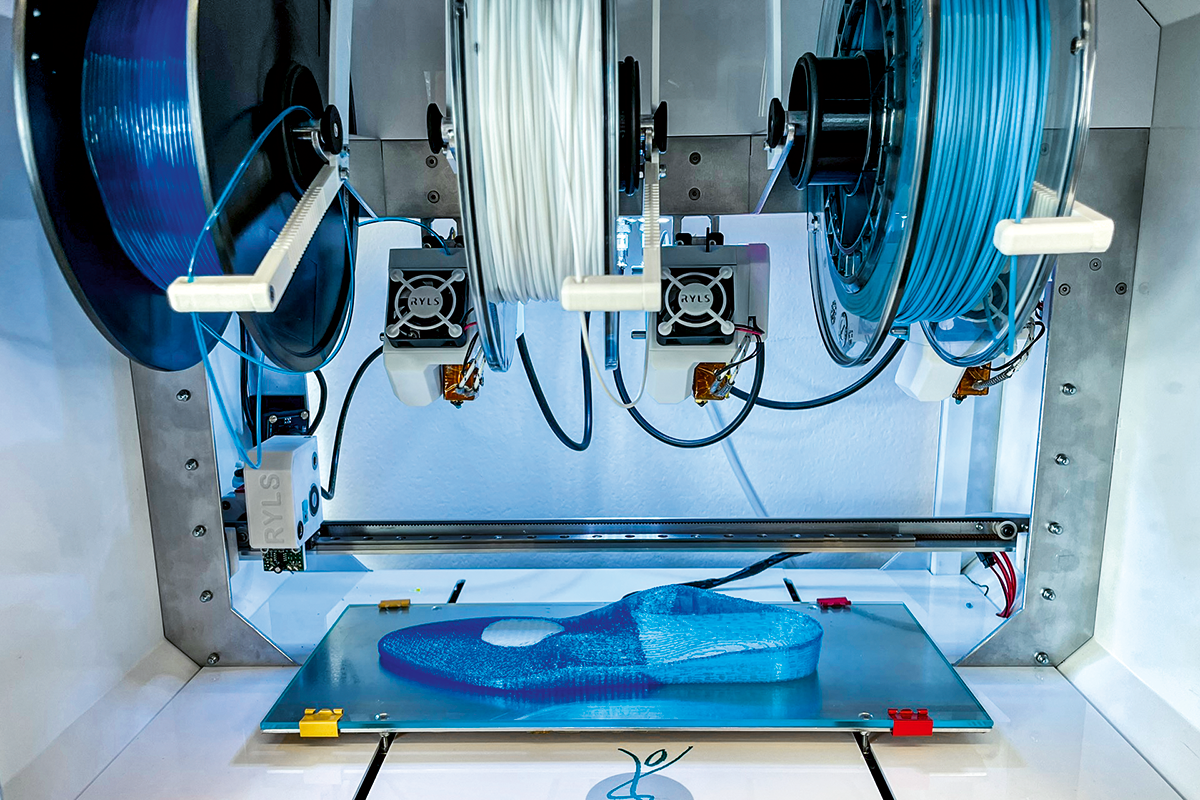

Yves Letz and Roman Santschi from Seiler’s team began by designing a fused deposition modeling (FDM) 3D printer capable of managing at least four different types of soft materials that can help relieve pressure. They engineered new printheads to accommodate materials with degrees of flexibility ranging from 60 to 90 shore A. The printer can automatically switch materials and printheads based on the insole designs it receives. These innovations enable the 3D printer to produce insoles that meet diverse comfort and support requirements.

But let’s take a step back: how are personalised insole designs created in the first place? A 3D scan of the foot combined with dynamic foot pressure measurements are used with clinical data such as varus/valgus legs as input for the insole design. Based on three decades of real data and experience from Orthopodo Malgaroli, Seiler’s team is developing artificial intelligence models and algorithms that can automatically design customised insoles for patients.

“Our shared vision is for patients to come into a clinic or a store, scan their feet and have the computer create a 3D insole model. The insole will then be produced by the 3D printer. Within one hour, patients can walk out wearing their new custom-made insoles” says Seiler.

Thinking ahead, the partners have conceptualised a user-friendly interface for the foot measurement and printing platform for point-of-care and point-of-sale settings. A stackable design will accommodate multiple printers vertically, for clinics that produce many insoles each day. Finally, Seiler’s team is refining a secure cloud solution for patient or customer data storage and processing.

“The 3D printer developed by the FHNW now gives us the opportunity to produce orthopaedic insoles quickly and sustainably” says Mario Malgaroli, owner of Orthopodo Malgaroli. “In the future, it could be used not only in our offices, but also in doctors’ offices, by podiatrists and physiotherapists, and in shoe and sports stores.”

Seiler believes it could also be used to triage normal support requirements from medical conditions that require the expert advice of podiatrists, acting as a diagnostic device.

The transition to automated design and 3D printing of insoles is a paradigm shift for orthopaedic firms. “The FHNW has helped Othopodo derisk the transition to Manufacturing 4.0 by making advanced knowledge accessible and workable in practical, real-world situations” says Seiler.

In the next step of the project, a trial is planned to validate the effectiveness and accuracy of the automated insole manufacturing process. This will involve testing the 3D-printed orthopaedic insoles in real-world conditions to ensure they meet patient or customer comfort requirements.

Seiler’s group is also starting a new project financed by the Forschungsfonds Aargau to refine the soft material filaments used to produce the insoles and give them antimicrobial properties. This work is being conducted in collaboration with the Institute for Chemistry and Bioanalytics and the Institute of Polymer Engineering.

Lastly, the team is aiming to reduce the amount of glue needed between layers of different materials by integrating the glue into the printing process. They are also designing new soft materials that will be recyclable, two further steps toward increased sustainability of customised insoles.

Key facts | |

|---|---|

Patients / Target Groups: | Foot misalignment patients, Adults with reduced balance, Standing occupations, Sports |

Partners: | Orthopodo Malgaroli |

Financing: | Innosuisse Project 107.955 IP-LS Forschungsfonds Aargau Project 20220930_17 Forschungsfonds Aargau Project 20240331_03 |