Additive Fusion Technology for 3D printed CFRP parts

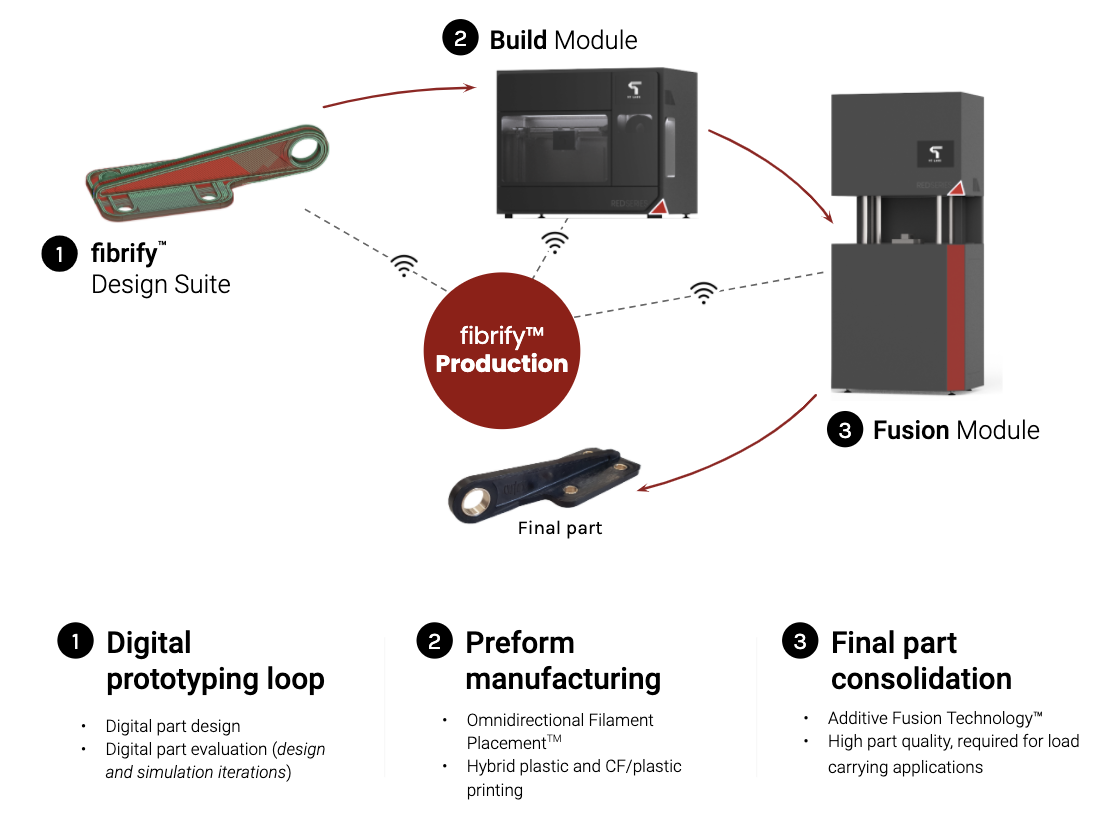

The traditional production of CFRP components is very time-consuming and expensive. The Swiss start-up 9T Labs has therefore developed a new method with which composite parts can be produced in large numbers using 3D printing and post-consolidation.

The Swiss start-up 9T Labs enables digital series production of structural CFRP components. Through innovative manufacturing processes, customers benefit from both a cost advantage and optimal component behaviour. High-performance polymers such as PA12 and PEKK are combined with industrial-grade carbon fibres to achieve a high fibre volume of up to 60%. This is necessary to open up load-bearing structural applications. By digitally modelling the process, a highly optimised composite component can be produced. Numerical methods from design to processing allow a weight reduction of over 40% compared to classical metal construction.

A disadvantage of components manufactured by Fused Filament Fabrication (FFF) is the adhesion between the filaments and the resulting mechanical performance transverse to the print direction. Through a proprietary second process step, post-consolidation (Additive Fusion Technology™), high mechanical performance can be achieved. This second process step makes it possible to open up entirely new applications that go far beyond prototyping.

With the Fibrify® design and production software developed by 9T Labs and a holistic process simulation as well as the Additive Fusion Technology™, the printed CFRP components are manufactured in industrial quality.

By determining thermal and mechanical properties of the printing filament and post-consolidated test specimens, pressure settings were defined and the parameters for the process simulation were created.

The interlayer adhesion and the shear strength were determined with an Arcan-modified test set-up and the corresponding consolidated butterfly test specimens. It was found that the strengths are strongly dependent on the consolidation pressure and temperature, but less so on the consolidation time. Computer tomography (CT) analysis of flat test specimens with a 0°/90° lay-up shows a significant reduction in porosity and an increase in the degree of consolidation at higher consolidation temperatures and pressures.

Client | |

Execution | |

Dauer | 30 months, starting January 2020 |

Förderung | |

Projektteam | Prof. Dr. Christian Brauner, Igor Zhilyaev, Marco Küng, Stefan Grieder |