Functional prosthetic legs made of glass fiber reinforced plastic recyclate

Worldwide, 35 to 40 million people depend on prostheses and orthopedic services. Project Circleg has therefore the goal to develop a prosthetic leg system that is adapted to the needs of People with an amputation in low to middle income countries.

Glass fiber reinforced plastic recyclate, prototype mold, transfer molding

Prosthetics that are available in developing countries usually lack functionality or availability. For this reason, the company Project Circleg has the goal to develop a functional prosthesis that is cost-effective and appropriate for the user. This prosthesis will initially be marketed in Kenya and Uganda. To use the infrastructure and machines of these countries, the locally available resources are to be utilized. The material for the prosthesis will be PP or PET pellets from recycled plastics. The recycled material will be sourced from the company Mr. Green from Nairobi, Kenya.

The FHNW Institute of Polymer Technology carried out a material and process investigation and prototype production. For this purpose, a component of the Project Circleg prosthesis system was optimized regarding a prototype production, suitable for plastics and for the production processes locally available in Kenya and Uganda. Subsequently, a tool was designed, manufactured and put into production. The main objective was to produce prototypes from the materials polyethylene terephthalate (PET) and polypropylene (PP) with short glass fibers (GF) and long glass fibers (LFT).

Various combinations of plastic recyclates with glass fibers were created, tested and compared. Once the most promising materials were selected, the second step was to test the feasibility of production.

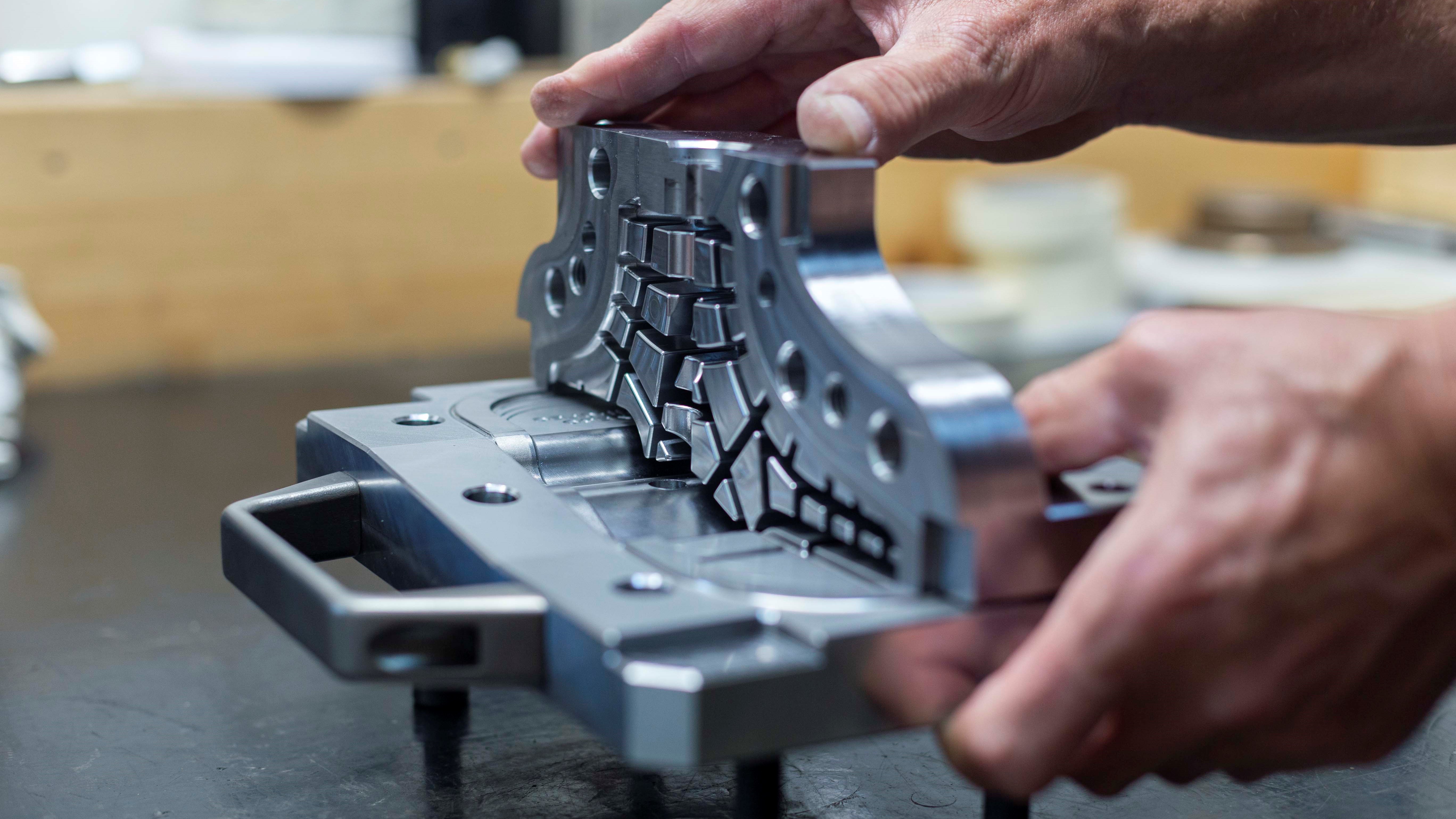

For this step of the development, a component of the Circleg prosthetic system was selected and the design was adapted according to the plastic construction rules to a simplified injection molding process, and then a prototype mold was developed and manufactured. Since the prosthetic parts are to be manufactured in developing countries, the transfer injection molding process was used. In this process, the plastic granules, as well as the mold, are heated in an oven above the melting temperature of the polymer. The molten polymer is then pressed into the mold by a press and cooled. The advantages of this process are the gentle processing of the fibers, which has an enormous influence on the impact strength of the material, and the lower investment costs in machines and equipment compared to the traditional injection molding process.

The development of the tool, as well as the production of the prototypes, was carried out in cooperation with the Swiss company Swissfluid AG, which is specialized in the transfer injection molding process. After coordinating the correct parameters and process steps, the production of the first small series was successfully carried out.

Client | |

Execution | |

Duration | 1 semester |

Team | FHNW: Prof. Dr. Christian Rytka, Simone Battaglia, Project Circleg: Simon Oschwald, Fabian Engel, Daniel Vafi, Laura Magni Swissfluid AG: Markus Meier |