Compressed air energy storage

Development of a compressed air energy storage system that not only stores energy but also provides heating and cooling for buildings. The main objective was to develop a bidirectional machine that functions as both a compressor and an expander.

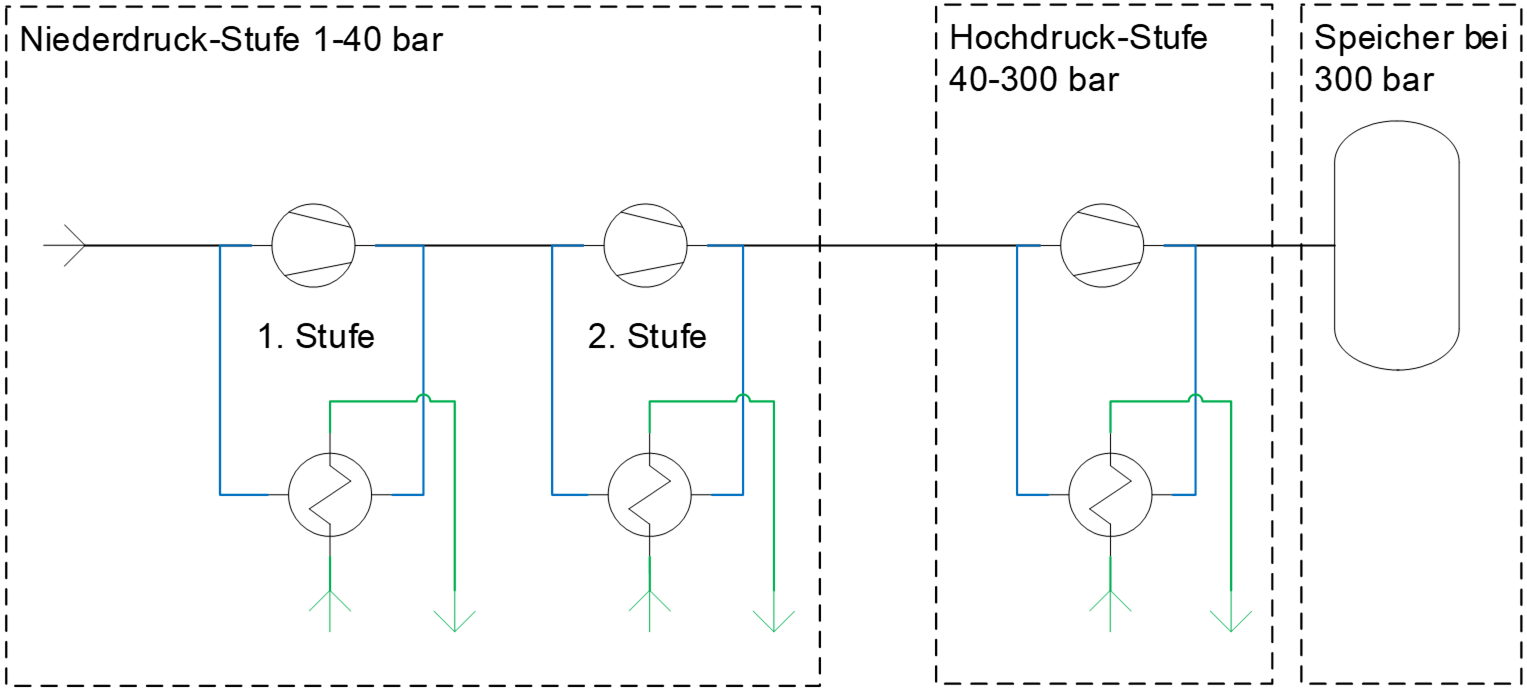

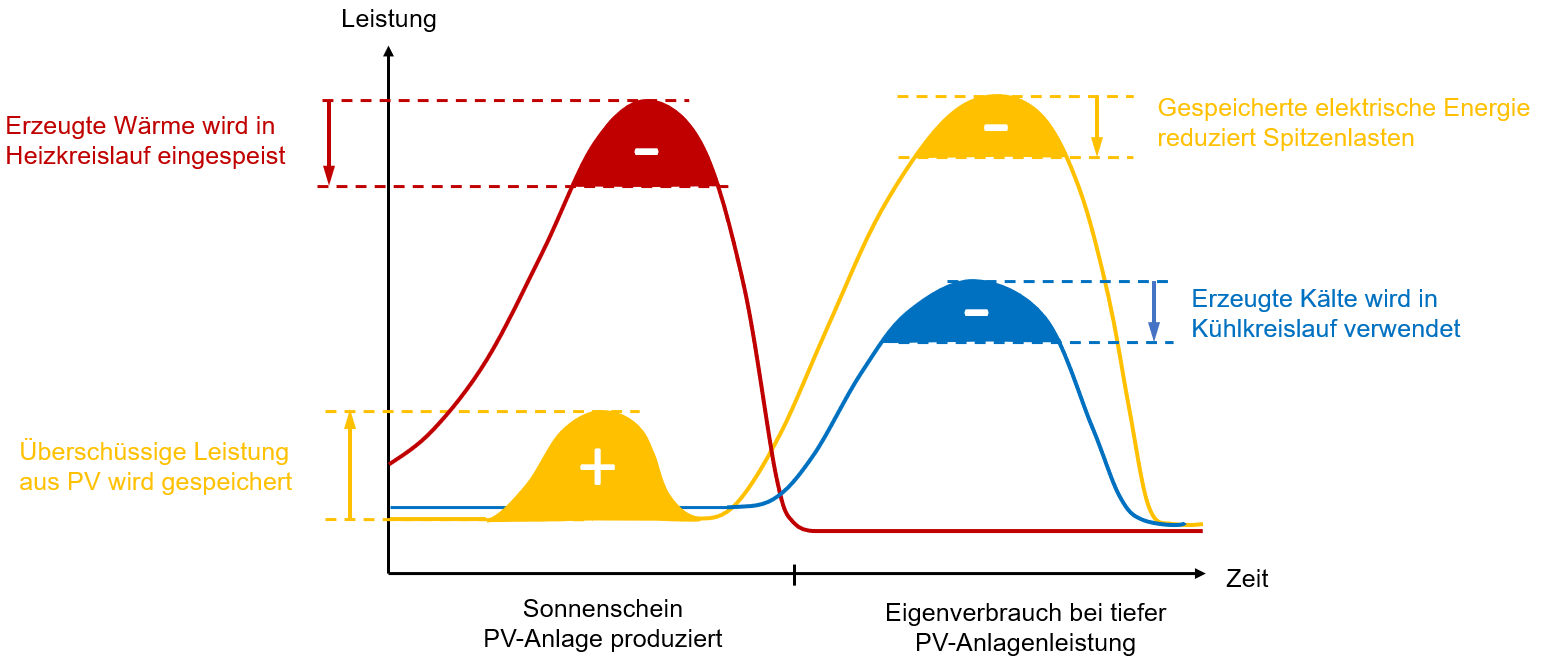

Renewable energies such as wind and solar require efficient storage technologies. Green-Y Energy AG is developing a compressed air energy storage system that also utilises the process-related generation of heat and cold. When the storage unit is charged, air is compressed to 300 bar and stored in compressed air cylinders. The resulting heat can be utilised in the building's heating circuit. During discharging, the compressed air is expanded and electricity is generated by a generator. The cold generated by the expansion of the air is fed into the building's cooling network.

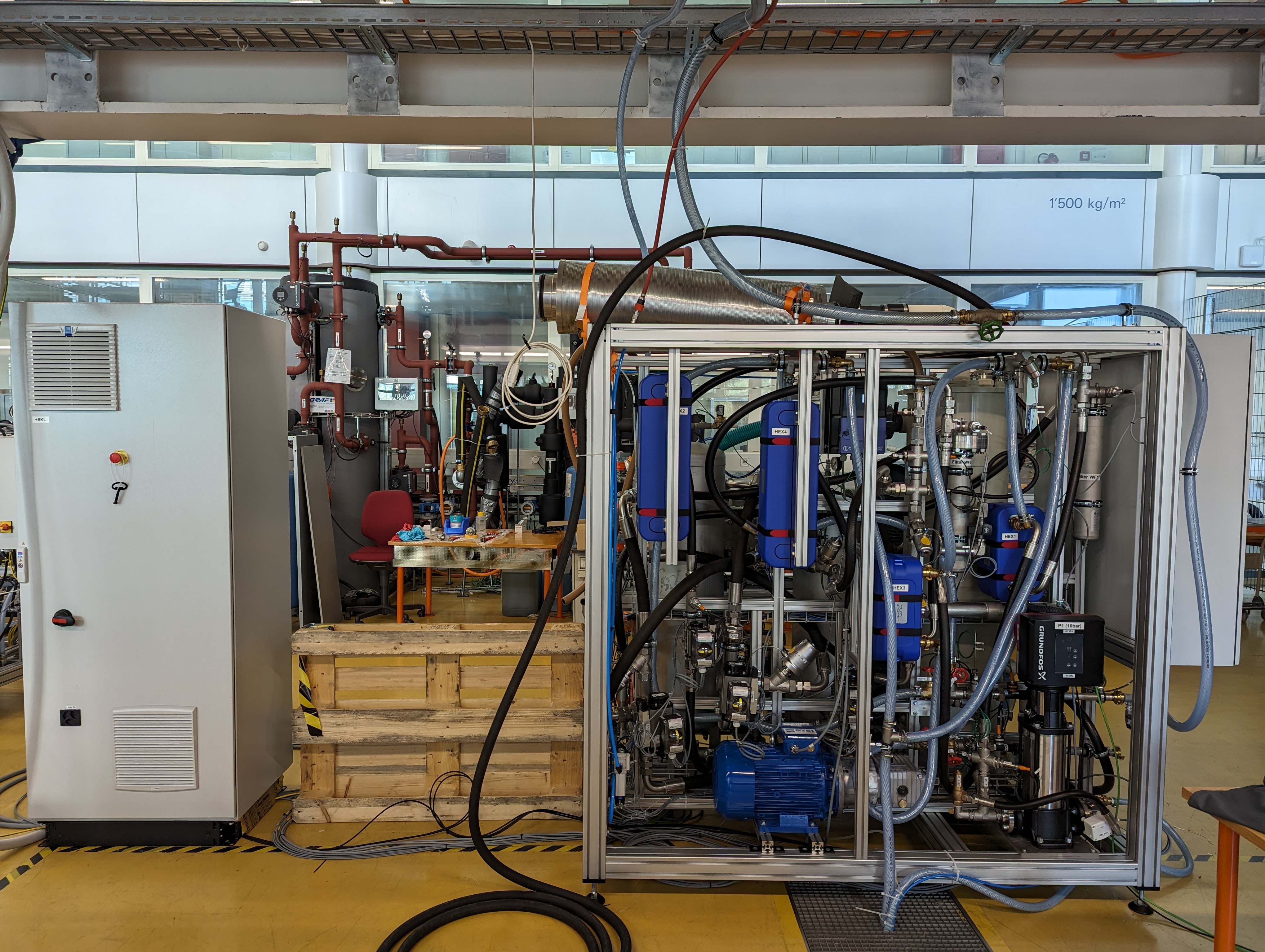

In the innovation project, supported by Innosuisse, the low-pressure stage of the compressed air storage system was developed and built by the ITFE. It is based on a volumetric compressor and is therefore the first of its kind. In contrast to the battery, the electrical-to-electrical efficiency is lower, as the conversion from electrical to pneumatic energy causes greater losses. However, the heat and cold generated turn the accumulator into a heat pump, which makes this system unique.

The aim of the project is to develop the low-pressure stage of the compressed air energy storage system based on a market-proven compressor technology, to use it as an expander and ultimately to combine it in a bidirectional machine. In the bidirectional system, the gas is compressed and expanded using the same machine. The efficiency of the system must be increased from electrical to electrical in order for it to be economical. The temperature levels of heating and cooling must also be adapted to the requirements of the building network.

In the first phase of the project, a volumetric compressor was converted into an expander and it was demonstrated that both electricity can be recovered and cooling can be provided for use in industrial buildings. In the second phase, the system was simplified with a new, bidirectional system. Compressor and expander were combined in one machine, which significantly reduced the acquisition costs.

The compressor was successfully operated at an outlet pressure of 40 bar and the heat was tapped at the required temperature level. Compressed air was successfully expanded via the expander and converted into electricity and cooling.

At the same time, Green-Y Energy AG developed the high-pressure stage, which covers the pressure range from 40 bar to 300 bar, in order to store the compressed air in cylinder bundles. The low-pressure stage from the first phase underwent intensive further development in Green-Y's laboratory during the project in order to improve its efficiency. The bidirectional machine has now been integrated into Green-Y's building as a pilot system and smoothes out the load peaks of the photovoltaic system.

Client | |

Execution | |

Funding | |

Duration | 30 months |

Project team | Beat Ribi, Bruno Schneider, Edgar Brodmann, Markus Birchmeier, Lea Ulrich, Linus Walker, Carsten Hersberger, Mario Ackermann |