Masks on the experimental test rig: How well do they protect against fine aerosol particles?

The Particle Measurement Technology Group of the Institute of Sensor and Electronics FHNW has developed a test rig to assess the filtering efficiency of various materials used in disposable and reusable masks.

Which masks protect effectively against viruses? This question has been on the agenda since the outbreak of the corona virus SARS-CoV-2 at the beginning of 2020. The demand for disposable and reusable protective masks has increased enormously worldwide - and could not be covered by the existing supply. The limited production capacities of existing manufacturers have resulted in textile companies, importers and distributors adding protective masks to their product range. But what properties must the filter materials have in order to provide the most effective protection against viruses or fine aerosols with a diameter of less than a thousandth of a millimeter?

If a person wearing a mask directly coughs or sneezes on you, even simple fabric masks can catch a large proportion of the droplets that are emitted, which are usually up to one millimeter in size. This means that the wearer of the mask protects fellow human beings from infection.

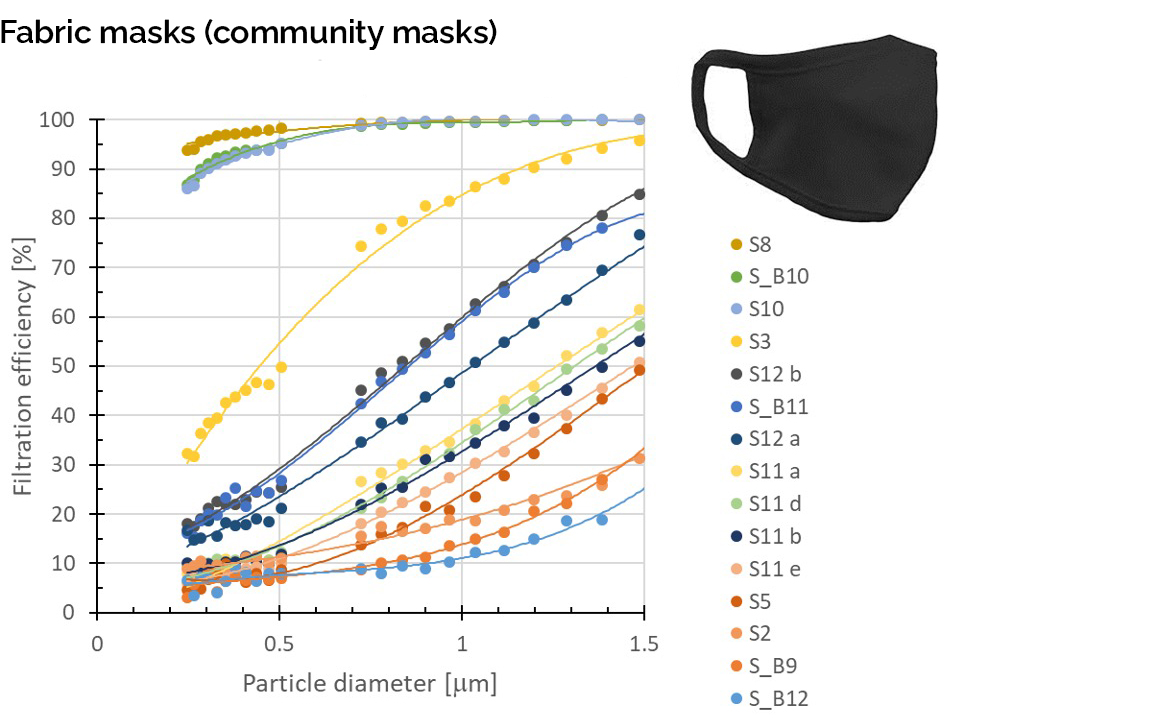

However, during normal breathing - and especially when speaking and singing - fine droplets and aerosols are also released with every breath. These are so small (< 5 microns) that they can float in the air for hours and can only be filtered by efficient masks. Since these sub-micrometer sized aerosol particles can also contain corona viruses, the transmission path through them is becoming increasingly important. This is especially the case because we often spend time in insufficiently ventilated indoor spaces and are therefore exposed to longer standing air with possibly increased concentrations of virus-carrying aerosols. We found that simple fabric masks usually offer neither the wearer nor the people around them protection against these ultrafine particles.

For an effective filtering effect of the mask, the fiber material must have the correct pore size and pore length. This is the only way to ensure that on the one hand small aerosols are deposited by diffusion on the filter fibers, while on the other hand larger aerosols impact on them due to their inertia. These two processes depend, among other things, on the speed at which the person breathes through the mask.

To ensure that the mask can be worn over a longer period of time, it must also be designed in such a way that the breathing resistance does not exceed a defined, maximum limit value. The breathing resistance is proportional to the pressure drop caused by the filter. In addition to these material science requirements, other factors such as a "good and tight fit" of the mask to the face are crucial for good protection.

Thanks to our aerosol expertise, we have been able to contribute to the further development of filter materials in recent months with measurement tests of mask filter materials for the Federal Department of Defence, Civil Protection and Sport (DDPS) and various Swiss textile companies, among others. For the Swiss consumer magazine "Beobachter", we carried out random tests on the aerosol filtration capacity of various fabric masks, hygiene masks and respiratory masks available on the market in July 2020. We found that commercially available masks filter fine aerosols with varying degrees of effectiveness. The assessment was carried out in accordance with the specifications of the Swiss National COVID-19 Science Task Force (NCS-TF) and the European standard EN 14683, using the above-mentioned DEHS as test aerosol for aerosol sizes of 300 nm and 1 µm.

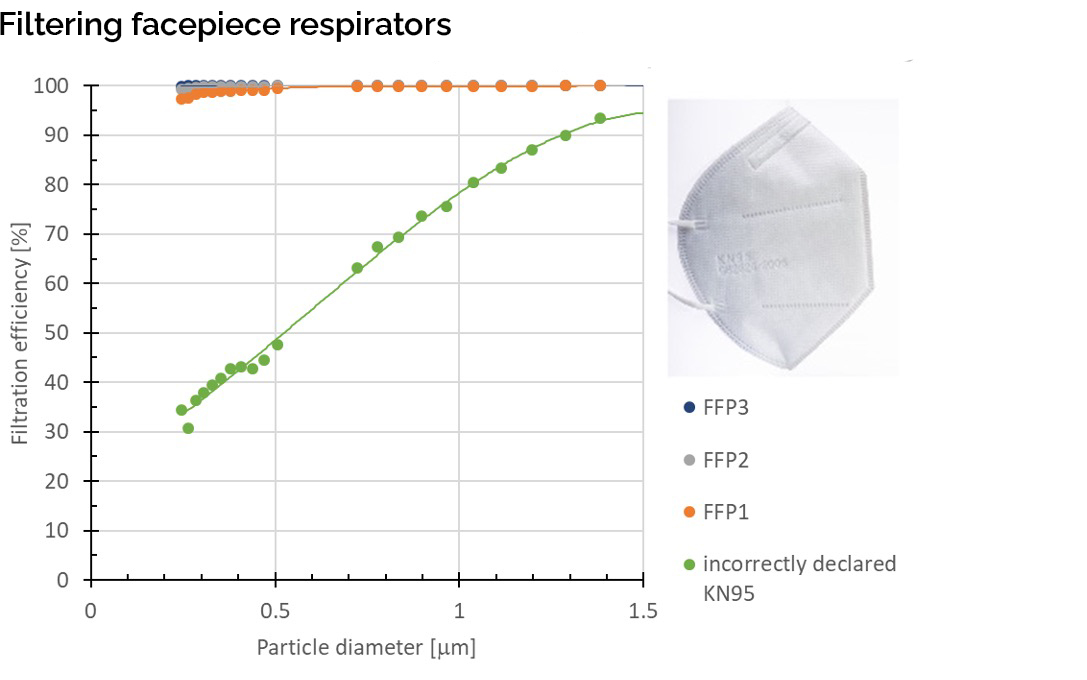

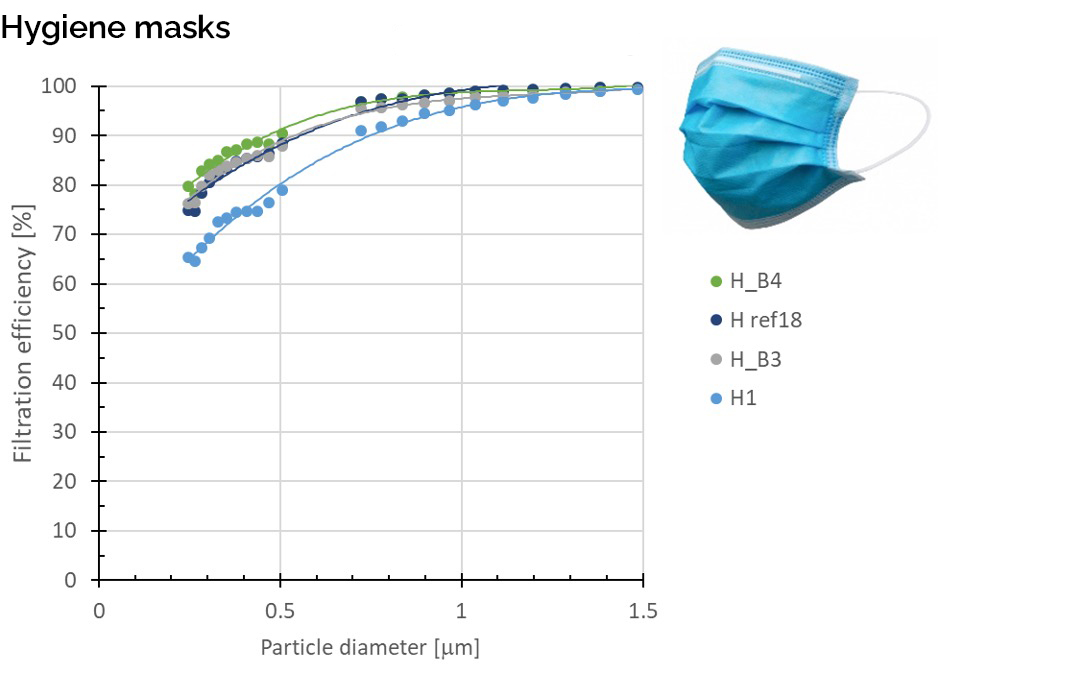

There is a great need in the general population for more clarity about which mask type provides good protection against the virus. Therefore, typical deposition efficiency curves, which we measured in our test facility for various masks available in Switzerland, are listed below.

In the following graphs the filtration efficiency of the masks (vertical axis, in percent) is shown for a wide range of particle sizes (horizontal axis). The individual tested masks are marked with anonymized abbreviations. The measurement results are divided into the three main mask types mentioned above.

Our recommendation to the consumers who want to get a good fabric mask: Obtain information from the seller / importer of the masks. Does he know the filtration performance of his product and can he show test reports or labels from trustworthy institutes? Here too, quality has its price.

In general, every mask is better than no mask at all, especially with regard to the protection of fellow human beings. In order to effectively protect oneself from aerosols, however, the mask must filter fine particles well. And regardless of the type of mask, make sure that it fits well on the face and seals tightly when worn. Even the best filter material is useless if the air you breathe passes the mask unfiltered.

Clients | Federal Departement of Defence, Civil Protection an Sport and other companies |

Execution | |

Project team | Nadine Karlen, Tobias Rüggeberg, Prof. Dr. Ernest Weingartner |