LiteWWeight®: An innovative multi-material joining technology for sandwich materials

The new technology has reached industrial maturity thanks to the collaboration between MultiMaterial-Welding AG and the Institute of Polymer Engineering at FHNW.

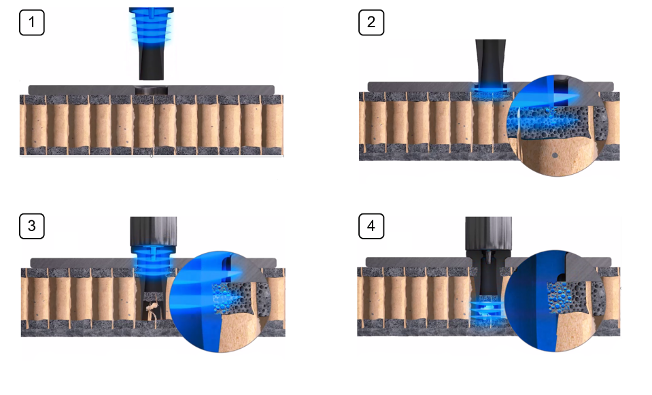

The company MultiMaterial-Welding AG has developed and patented an innovative platform consisting of different products and solutions that offer a new method to join different materials. One of those is the MM-Welding® LiteWWeight® technology, which is especially designed for sandwich structures with honeycomb and foamed core materials. Ultrasonic energy is used to insert a thermoplastic connection element through the top-layer into the porous structure of the core. Thanks to the ultrasonic excitation, the thermoplastic connection element melts at the interface, infiltrates the porous structure and creates a highly interlocked bond with the substrate material.

Dealing with the mechanical behaviour is the key to success. For this reason, experimental and numerical methods were developed during the project with the company MultiMaterial-Welding AG in order to better understand the dynamic and fast process.

An online process monitoring of the LiteWWeight® technology was developed to acquire and evaluate high-resolution process data such as reaction force and amplitude. It enabled an in-detail analysis between mechanical performance of the connection and the process parameters. In addition, a high-speed camera was used to obtain information about the rupture behaviour during the very short process such as buckling of the thermoplastic element. Furthermore, it was important to investigate the vibration charateristics of the thermoplastic fastener in more detail. By means of numerical analyses of the frequency behaviour and the elastic wave propagation, geometry and process could be optimised and thus stabilised. This project illustrates the high increase in knowledge through the coupling of experimental and numerical methods.

Client | |

Execution | |

Duration | 2017 - 2020 |

Funding | |

Team | Prof. Dr. Christian Brauner, Dr. Igor Zhilyaev, Lucian Zweifel |