Periodic technical inspection for diesel soot emissions

In order to check the exhaust gases of road vehicles regularly, researchers from the FHNW have developed a portable measuring device .

With the introduction of particulate filters, particulate emissions from internal combustion engines fell very sharply. A good filter has an efficiency of well over 99%. Often the concentration in the exhaust gas is then lower than in the ambient air. At about the same time, various on-board diagnostic systems were introduced. In the opinion that these would detect a malfunction of the exhaust gas purification systems, the exhaust gas test was abolished.

Meanwhile, it is becoming increasingly clear that while emissions are very low when filters are intact, a small percentage of filters are either defective or have been tampered with, or even removed altogether. Even small defects can increase emissions by orders of magnitude. This leads to a situation where a few engines with very high emissions dominate fleet emissions (Fig. 1).

This is true for road vehicles as well as for off-road applications (construction machinery, etc.). This is why periodic emission monitoring needs to be reintroduced. For construction machinery and other off-road engines, this is already the case in Switzerland.

In order to carry out the monitoring in practice, suitable measuring instruments with following features are required:

- Allows easy measurement of particle number concentrations

- Since the entire sensor is heated, emission measurements can be made without dilution

- Concentration range up to 5,000,000 particles/cm3.

- Long maintenance interval as no liquid, no dryer is used and only a few particles are deposited in the instrument

- Can be used standalone or communicate with PC/tablet via Bluetooth, where the report is also generated for official measurements.

- Is METAS certified according to regulation SR 941.242 (certificate CH-K4-20002-00)

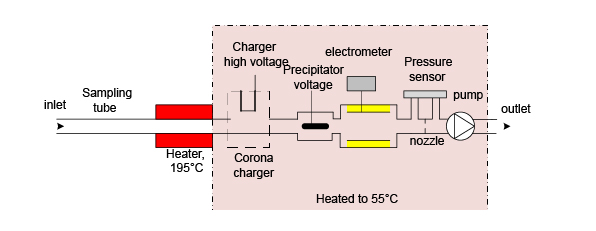

In a project funded by the Swiss Federal Office for the Environment (BAFU) researches of the FHNW have developed a Handheld Emission Particle Counter (HEPaC). It is based on the Partector 2 of the company naneos, a spin-off of the FHNW.

The HEPaC can be purchased at naneos, an FHNW spinoff.

The HEPaC can be used for following applications:

- Emission measurements of combustion engines

- Official periodic control measurements according to Swiss ordinance SR 941.242 for construction machinery and other off-road engines

- Fleet emission tests

- Burtscher, H. Lutz, Th. und Mayer, A. (2019) A New Periodic Technical Inspection for Particle Emissions of Vehicles. Emission Control Sci. and Technol. 5(3), 279-287.

- Fierz, M., Meier, D., Steigmeier, P., und Burtscher, H.(2014) Aerosol Measurements by induced currents. Aerosol Sci. and Technol., 48, 350-357.

- Product flyer

- METAS certificate

Client and funding | Swiss Federal Office for the Environment (BAFU), BAFU Umwelttechnologieförderung, Vertrag UTF 601.1319 |

Execution | |

Duration | 2 Years |

Project lead |