Quality enhancement through digitalisation

Using digital technologies, Biotronik significantly increases the quality of its products.

- Industry 4.0

- medical technology

- Extrusion

- Digital twin

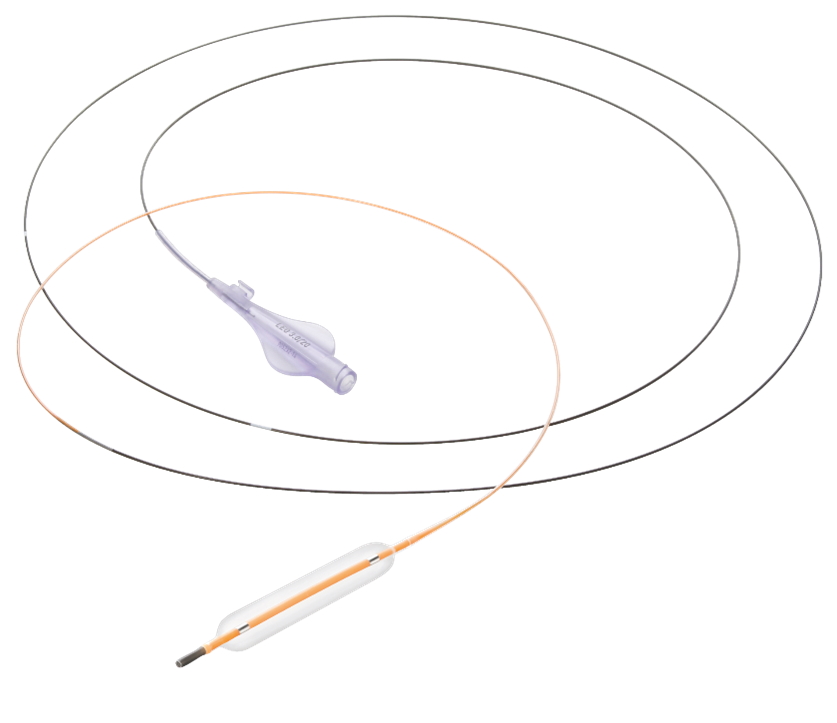

The production of catheter balloons at Biotronik runs in a multi-stage process, whereby the individual process steps are carried out largely independently of each other. No digital data evaluation or control systems were used.

Due to the lack of integration of the individual process steps, irregularities could not be detected sufficiently well and suitable intervention in the process was only possible to a limited extent. As a result, catheter balloons of very different quality were produced, including those of poor quality. The testing effort and waste was high and impaired the economic efficiency of the balloon production.

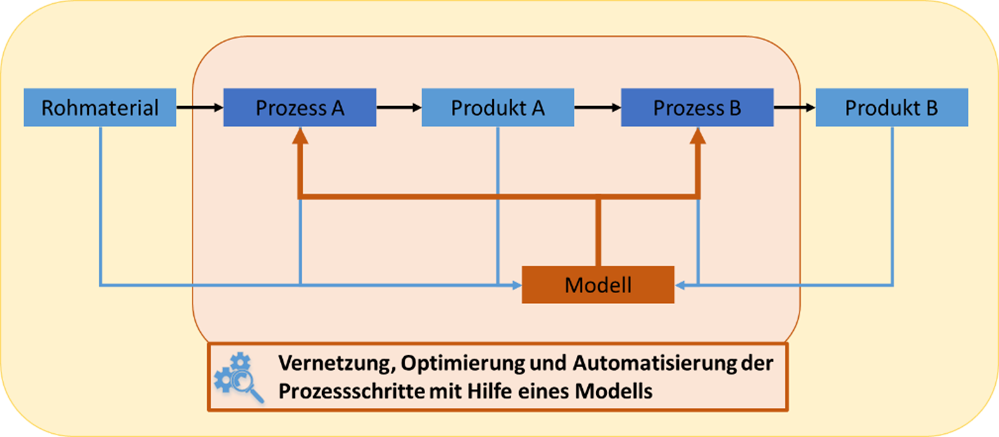

The main objective was to bring together the production steps in the manufacture of catheter balloons and to record a complete set of measured values for each manufactured catheter balloon. This makes it possible to easily monitor and optimize production digitally.

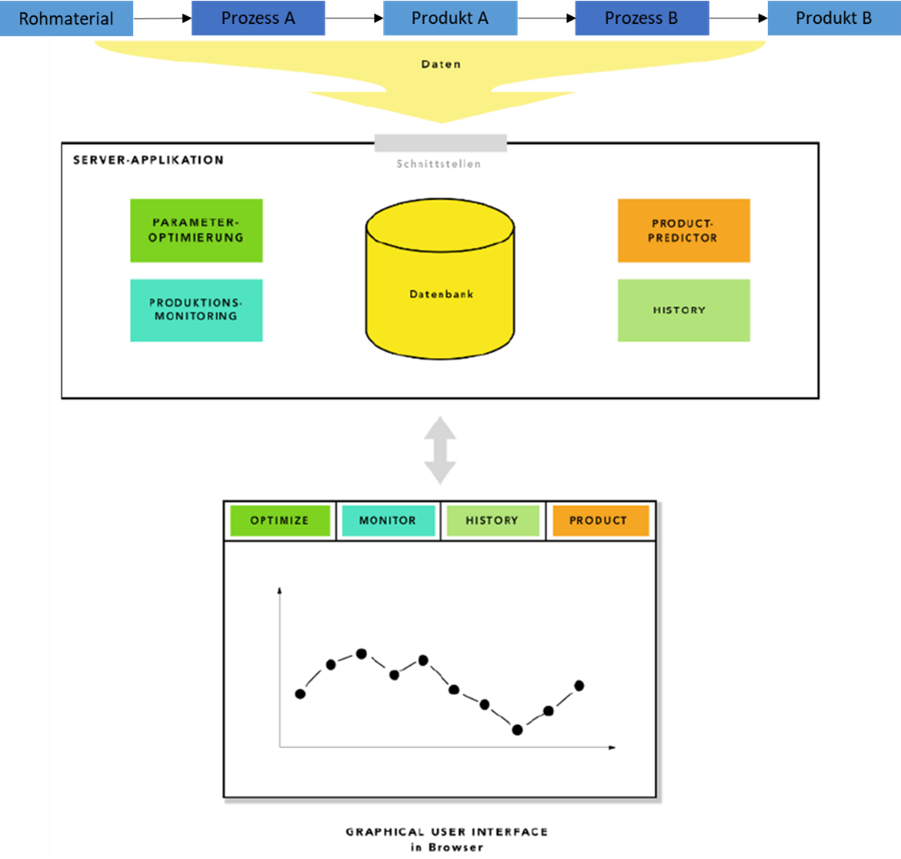

Production should be optimized across all processes regarding the properties of the products and production efficiency. For this purpose, a software application should be developed that centrally collects all data and makes it easily accessible for visualization, optimization, and prediction.

Throughout the entire process, modules for automatic data acquisition were installed, which capture all relevant data of a single balloon. On the one hand, this made it possible to investigate isolated interrelationships from a plastics technology perspective, and on the other hand, to develop and implement a flexible and adaptive, model-based end-to-end optimization approach. In the course of the project, it was thus possible to specifically collect new data to improve the model.

With the help of this approach, the scrap rate as well as the setup time can now be consistently reduced, and catheter balloons can be systematically produced with a more consistent and better quality.

Client | |

Execution | |

Duration | 2 years |

Förderung | |

Projektteam | Institut für Kunststofftechnik FHNW: Stephanie Wegmann, Alex Massenbauer, Prof. Dr. Christian Rytka |