Taking waste from the aviation industry to new heights

Researchers at the FHNW have developed a cost-effective and sustainable sole made of recycled carbon fibres for a running shoe by the Swiss sports brand On.

The Swiss sports brand On revolutionised the running shoe market with its striking and at the same time radical sole construction. Two innovative technologies, the CloudTec® midsole and the Speedboard®, are used in the process. The latter is a plate that connects the cloud-shaped elements with the upper shoe. The Speedboard® is bent with every step, absorbs the impact energy, and releases the energy stored in the clouds with every push-off.

The traditional Speedboard is made of a thermoplastic material, which, due to the mechanical properties of the material, loses a part of its impact energy despite its innovative sole design. Through the use of lightweight plastic construction principles in combination with the most modern materials and advanced design, more of the impact energy is to be stored in order to bring runners to maximum performance.

Evolution of Speedboard technology through the use of advanced materials, advanced design and an industrial manufacturing process. This further development should lead to a lightweight, stable, stiff but in some areas flexible, low-cost Speedboard which also contains sustainable recycled materials that can be reused after the shoe’s life cycle.

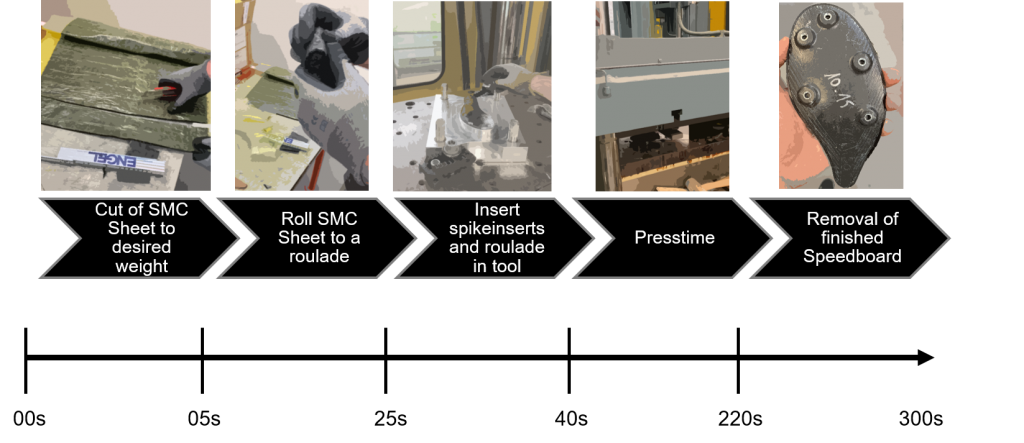

As a starting material, carbon fibre waste from the aerospace and automotive industries is reused, which is processed together with a thermosetting polymer to form a Sheet Molding Compound (SMC). The SMC material is cut to the required weight in the Speedboard production process, placed in the mold cavity and pressed for 5 minutes. After demolding, no additional adjustments are necessary and the Speedboard is ready for the joining process with the upper shoe.

The design for the new Speedboard was developed together with experts from On and their athletes, with a focus on biomechanical aspects during running. The developed Speedboard is undergoing final testing before athletes wear it in competitions. The project was nominated for the prestigious Jec-Awards in 2020.

Client | |

Execution | |

Duration | 32 months, Start: February 2018 |

Funding | |

Team | Prof. Dr. Christian Brauner, Stefan Grieder, Remo Stauffer |