Temperature and layer wear measurement for turbine blades

New methods for the in-situ measurement of surface temperature and coating wear in a test rig for rotating turbine blades.

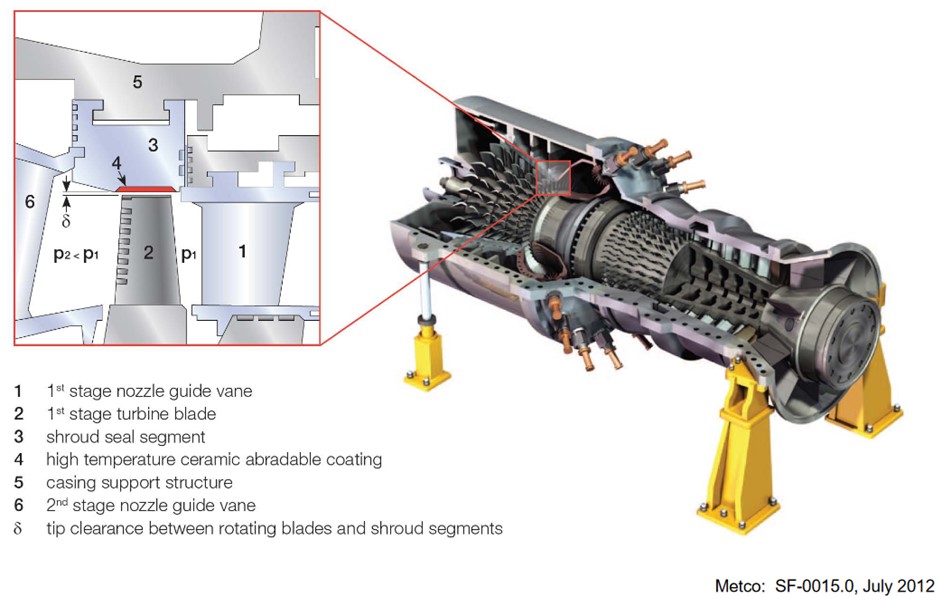

Surface technologies such as thermally sprayed scraper coatings for gas and steam turbines and turbochargers are used to control the gap between the turbine blade and turbine housing. They are optimised for a wide range of applications and load conditions. These coatings improve the operational reliability of the turbines and reduce fuel consumption and emissions. The turbine blade (2) and the scraper layer (4) form the sealing system of the gas turbine after the scraper process.

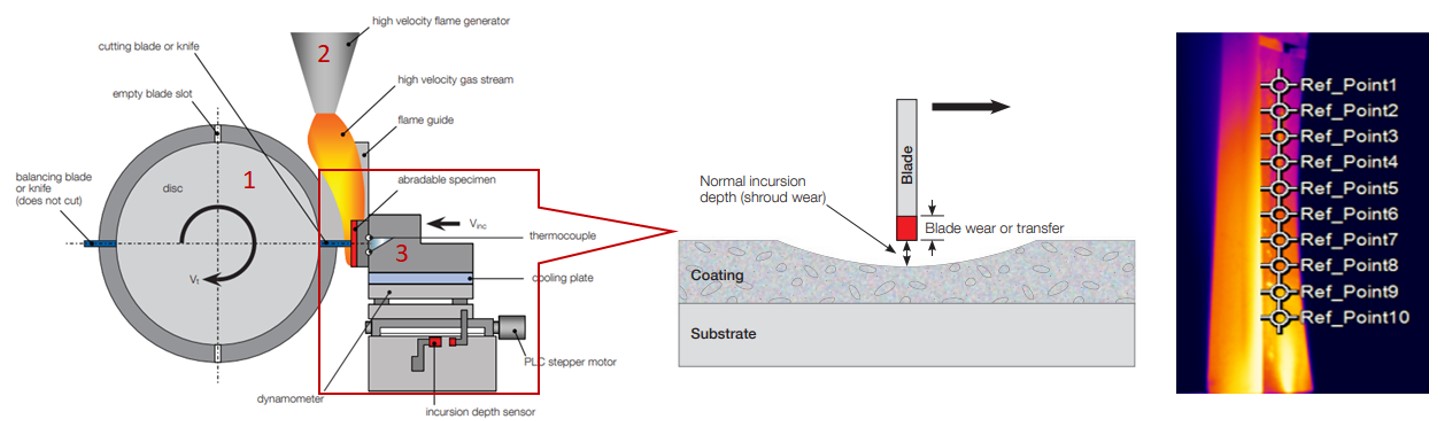

The wear mechanisms of the sealing systems are simulated under realistic conditions on an ‘incursion test rig’. This consists mainly of a rotor (1), an ‘incursion unit’ (2) and a high-speed burner (3). The temperature development is of great importance for the investigation of the processes during the contact strip process. This is recorded using a high-speed thermal imaging camera and serves as the basis for the assessment of new coatings.

Imaging methods in the infrared range are subject to considerable measurement uncertainty. Individual contributions to this have been experimentally quantified in the laboratory, thus significantly improving the overall uncertainty of this measurement on the test bench.

Client | |

Execution | |

Funding | |

Duration | 2 years |

Project team | Prof. Dr. Matthias Stark, Stefan Moser, Dr. Dario Wüthrich |