Safety first!

Andreas Zogg brings chemical engineering companies and students together to make shared advances in process safety

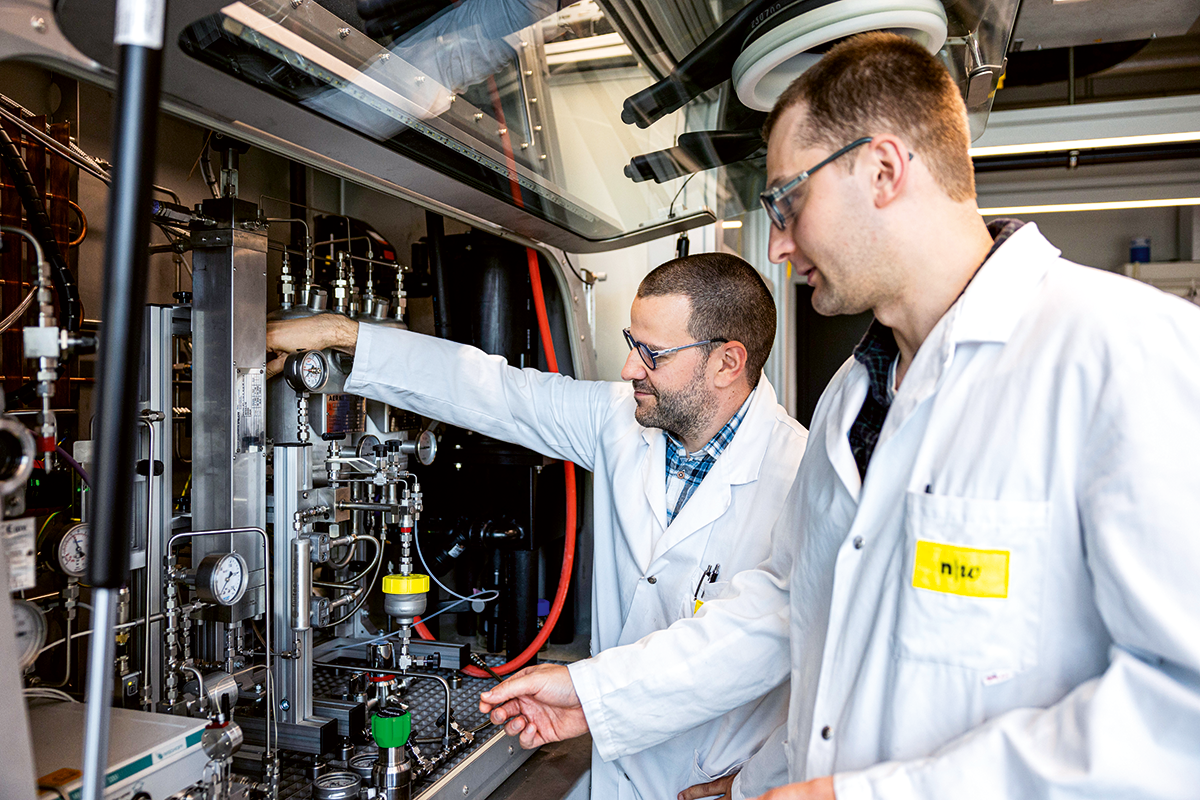

Prof. Dr. Andreas Zogg has a passion for process safety. He joined the FHNW School of Life Sciences in 2018 after serving as Safety expert at Novartis, and Process development chemist at F. Hoffmann –La Roche and Ciba SC for several years. Now he leads the process development group at the FHNW’s Process Technology Center. He is founder and president of the association Miniplant 4.0.

“Three drivers of innovation in today’s Swiss chemical industry are safety, sustainability and quality” says Zogg. “If you ask me, safety always comes first!”

Many chemical reactions performed to produce ingredients for detergents and cosmetics pose a danger of fire and explosion. Transitioning from batch or semi-batch reactions to continuous flow chemistry can provide safety advantages.

Second, as companies look to reduce their energy consumption, they see the opportunity to conduct some reactions in continuous mode to avoid costly energy peaks. This is creating a demand for continuous reactor systems deployed at smaller, decentralised production sites.

Finally, as the price of chemicals manufactured in Switzerland is high, their quality must be a differentiating factor. Scaling up flow chemistry helps promote the fine chemicals sector nationally.

Zogg is addressing all three elements in an Innosuisse project called Simulation-based safety concept for the scale-up of safety-related demanding continuous processes, performed in collaboration with MSc students from the FHNW School of Life Sciences and industry partners.

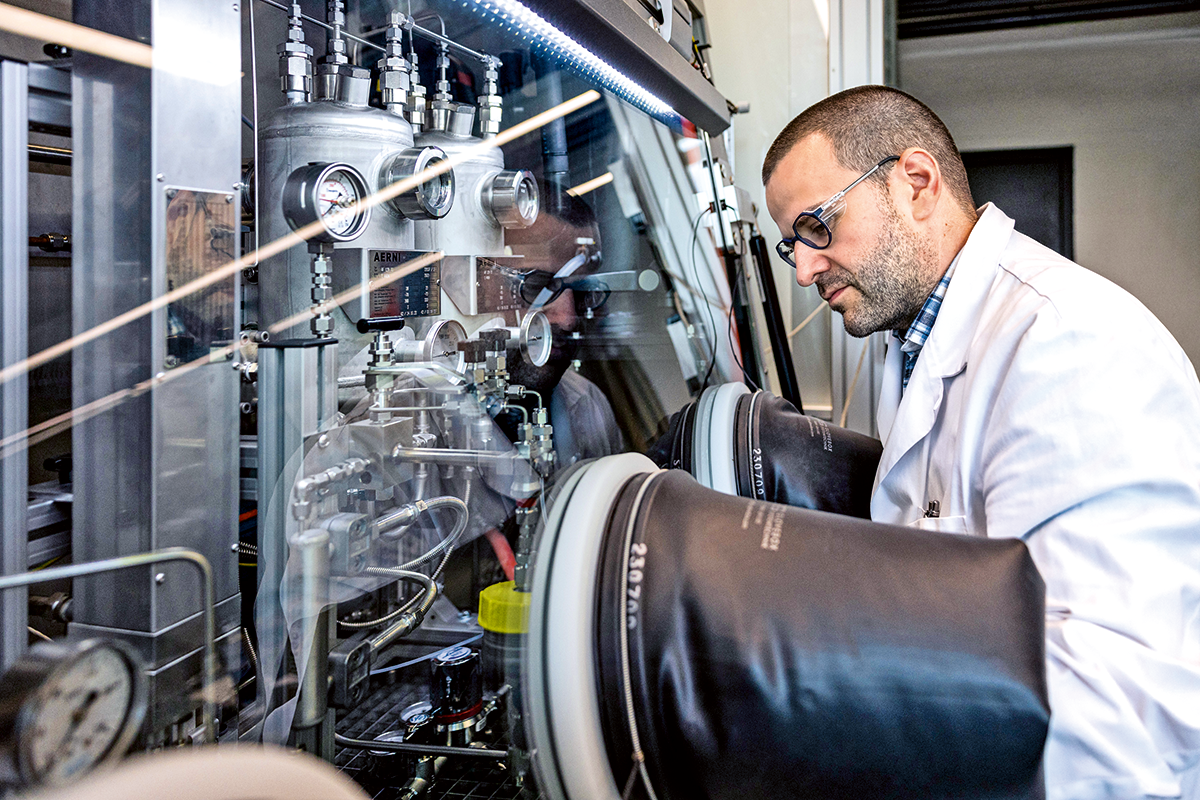

Zogg’s team is contributing a model to scale up a continuous ethoxylation reaction and determine when an explosion is likely to occur. The initial model is built on data in scientific literature about thermodynamics and reaction kinetics, combined with small-scale differential scanning calorimetry (DSC) measurements collected in the FHNW’s Process Technology Center explosion reactor.

To determine when the ethoxylation reaction is likely to cause an explosion, Zogg’s team modelled two scenarios and performed them within a unique explosion reactor, using the resulting vapor liquid equilibrium data to refine their model. Although they had modelled a maximum explosion pressure of 12 bar, the reaction was performed up to 20 bar before exploding.

Furthermore, Zogg’s team conceptualised the basic design of the continuous ethoxylation plant, including a comprehensive risk analysis (HAZOP).

Finally, they performed the flow reaction in a safety glove box that they designed specifically for this purpose. The box provides a nitrogen atmosphere, monitors oxygen and ethylene oxide levels and features an integrated safety washer to destroy ethylene oxide steam leakage.

Fluitec, a designer and manufacturer of reaction systems, is contributing a small-scale continuous reaction calorimeter to the project. This specialised device, which sits inside the safety glove box, measures the heat released from the reaction. The real-time data collected using Fluitec’s device is used to adjust the FHNW’s process model.

“Deploying our flow calorimeter in an experimental setting and contributing to new models for flow chemistry scale-up provides valuable insights about how the calorimeter performs at small and production scale" says says Marlies Moser, Fluitec.

The FHNW’s model, strengthened by data collected by Fluitec’s calorimeter, will be applied by the project’s implementation partner, Schärer & Schläpfer AG, a producer of surfactants for the pharma and chemical industry. The goal is to enable direct scale-up from lab to production volumes.

“The process safety models developed by the FHNW are enabling safer, more energy efficient reactions that produce high quality surfactants. We look forward to applying the models to scale up production in our facilities” says Roland Borner, Schärer & Schläpfer AG.

In addition to industrial innovation, the project provides hands-on educational opportunities. Two part-time MSc students, This Zahnd and Benedikt Brönnimann, are working on the Innosuisse project while completing their Master's in Chemical Engineering. BSc students in chemical engineering also carry out a portion of the work. The FHNW’s Miniplant facility, including its unique explosion reactor for testing the thermal process safety of explosive reactions, provides students with direct experience in hazardous process modelling and management.

“Especially for students at the Master's level, it enables them to deepen their knowledge in real-life settings before they graduate and fully transition to industry” says Zogg. “At the same time, it allows us to advance knowledge on how to safely scale-up flow chemistry processes to promote their adoption by industry.”

Key facts | |

|---|---|

Partners: | Fluitec, Schärer & Schläpfer AG |

Financing: | Innosuisse project 62273.1 IP-ENG |