Using bacteria against crude oil spills

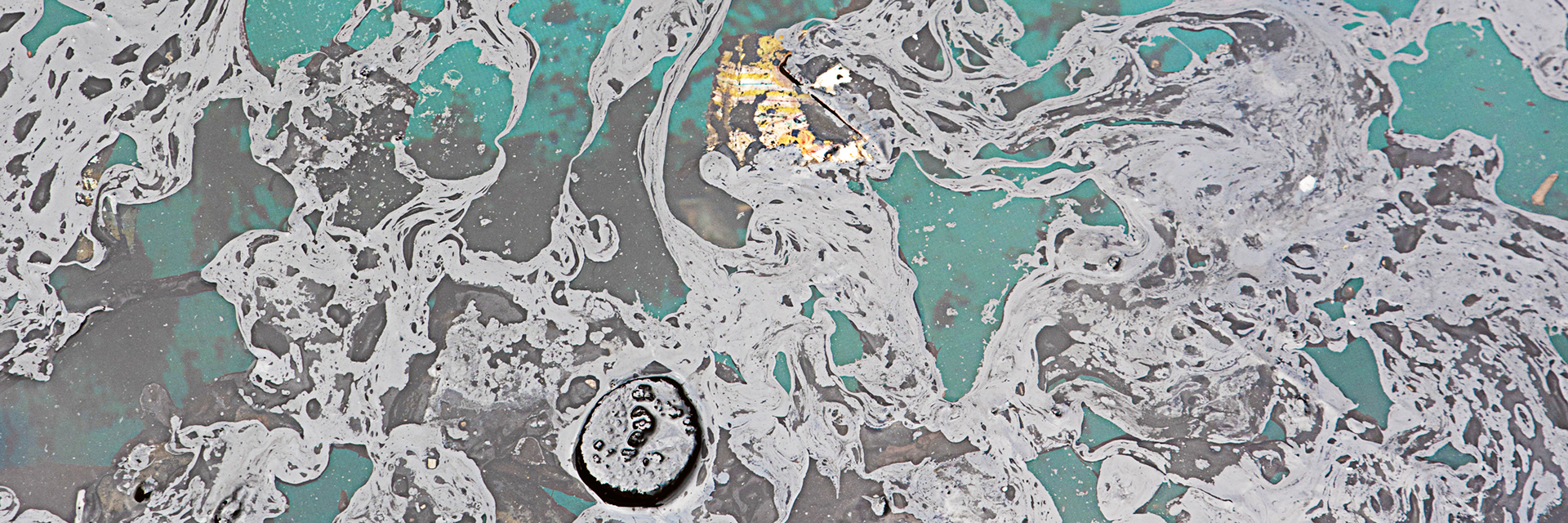

Crude oil spills are one of the greatest risks to the industrialised world. Oil spills in the sea are not only difficult to contain but also highly resistant to natural decomposition. HLS researchers have taken up the fight. As part of the EU Kill Spill project, they are working with more than 30 partners from science and industry, developing biotechnology techniques to clean up oil-polluted waters.

The EU Kill Spill project is an international network of research organisations and businesses which is playing a key role in dealing with crude oil catastrophes. This includes developing new technologies to solve several problems at once: the first aim is to contain oil spills more effectively or spread them more thinly, thereby aiding breakdown. Secondly, the breakdown process itself will be improved. Finally, the group are developing new environmental decontamination methods.

Given that the project is based on the self- cleaning abilities of the sea, researchers are concentrating on biotechnology solutions. Ocean microorganisms, especially bacteria, can break down tar and long-chain hydrocarbons from crude oil. This is the focus of the HLS team led by Philippe Corvini at the Institute for Ecopreneurship, and Patrick Shahgaldian and his colleagues at the Institute of Chemistry and Bioanalytics. The team are developing porous silica particles (SiO2) that provide bacteria with the additional nutrients they need to break down the oil. Up to now microorganisms have taken too long to do this and were therefore unsuitable for targeted cleaning of contaminated waters; mechanical methods such as floating booms were used. However, since these cannot absorb small quantities of oil, a thin film always remained. Solving this problem is one of the aims of the Kill Spill project.

Even the floating oil itself stops the bacteria breaking down the crude. The hydrocarbons in it are hydrophobic, adhering to one another, repelling water and accumulating in the floating mass. To counteract this, a Kill Spill team from Northern Ireland is working on a method of dispersing the oil by making the molecules more accessible to bacteria. However the microorganisms cannot break down the oil fast enough as the process is chemically limited. Corvini compares the problem to eating: “ It's like people, who need meat and vegetables. Bacteria require the right proportions of carbon, nitrogen and phosphorus in order to reproduce.” Crude oil consists mainly of hydrocarbons; bacteria thrive when nitrogen and phosphorus are added.

The problem with these “bacteria food supplements” is that they are diluted by the sea. This is caused by diffusion, as in still water, but is augmented by waves and currents. Corvini and Shahgaldian have designed a method using porous silica nanoparticles to release the required elements only when they are absorbed by the bacteria. Corvini explains the function of these tiny spheres, which consist of the same elements as glass: “Highly water- repellent molecules are anchored to the surface of the silica particles, which are loaded with nitrogen and phosphorus. These hydrophobic molecules close the pores of the silica particles in water. Like oil, these structures are hydrophobic, hence they accumulate on oil slicks. The pores open, releasing nitrogen and phosphorus precisely where the bacteria break down the oil.”

Since the silica spheres are so small they can be sprayed as a powder on to the oil spill from a helicopter or a ship. Although nitrogen and phosphorus have been used in the past to stimulate bacterial oil breakdown they had to be dissolved in vegetable oil. The new HLS process eliminates that additional pollution: the dry powder does with- out solvents or additional contamination. The researchers have already produced a kilogram of the bacterial nutrients and the next step is to scale-up the process; Corvini needs a hundred kilograms for the planned trials. He says: “ Initial results are very encouraging and we are now going to do further tests near Athens.” Corvinis's team are evaluating large-scale production and are upbeat about the chances of a successful spin-off.

- Chemical synthesis

- Bacterial cultures

- Breakdown tests

- Liquid-liquid extraction

- Gas chromatography

- GC-MS

- SEM

- Incubators

- OxiTop

- EU FP7

- Technical University of Crete

- Environmental Protection Engineering (EPE)