A world without friction? There is no such thing!

Friction is always present, whether you want it or not. Sometimes it is desired, and some-times it disrupts. At the Institute of Polymer Nanotechnology (INKA), it has recently become possible to investigate friction effects in detail.

Friction is omnipresent in our everyday lives and plays a decisive role. Friction occurs when two objects in contact are moved relative to each other. In some cases, high friction is desirable, for example between a shoe sole and the floor. We notice how unpleasant a lack of friction feels, especially on icy surfaces. In other cases, high friction is avoided at all costs. One might think of ski racers who prepare their sports equipment in such a way that they are slowed down as little as possible by contact with the snow.

An economically relevant aspect is abrasion, which is caused by friction. In everyday life, we know this from shoes: While the upper material of a shoe may still be in very good condition, the lower part has to be resolved after a certain time at the shoemaker. The countless contacts between the sole and the ground have led to abrasion, i.e., a loss of material from the sole.

In industrial applications, for example in machinery, efforts are made to keep abrasion as low as possible. Optimised material combinations are being researched for this purpose. To reduce friction and abrasion, lubricants are used between the material combinations. Greases, oils or even just water can extend the service life of components many times over.

All these aspects are studied in tribology, the science of friction, abrasion and lubrication. But how does one proceed in practical terms?

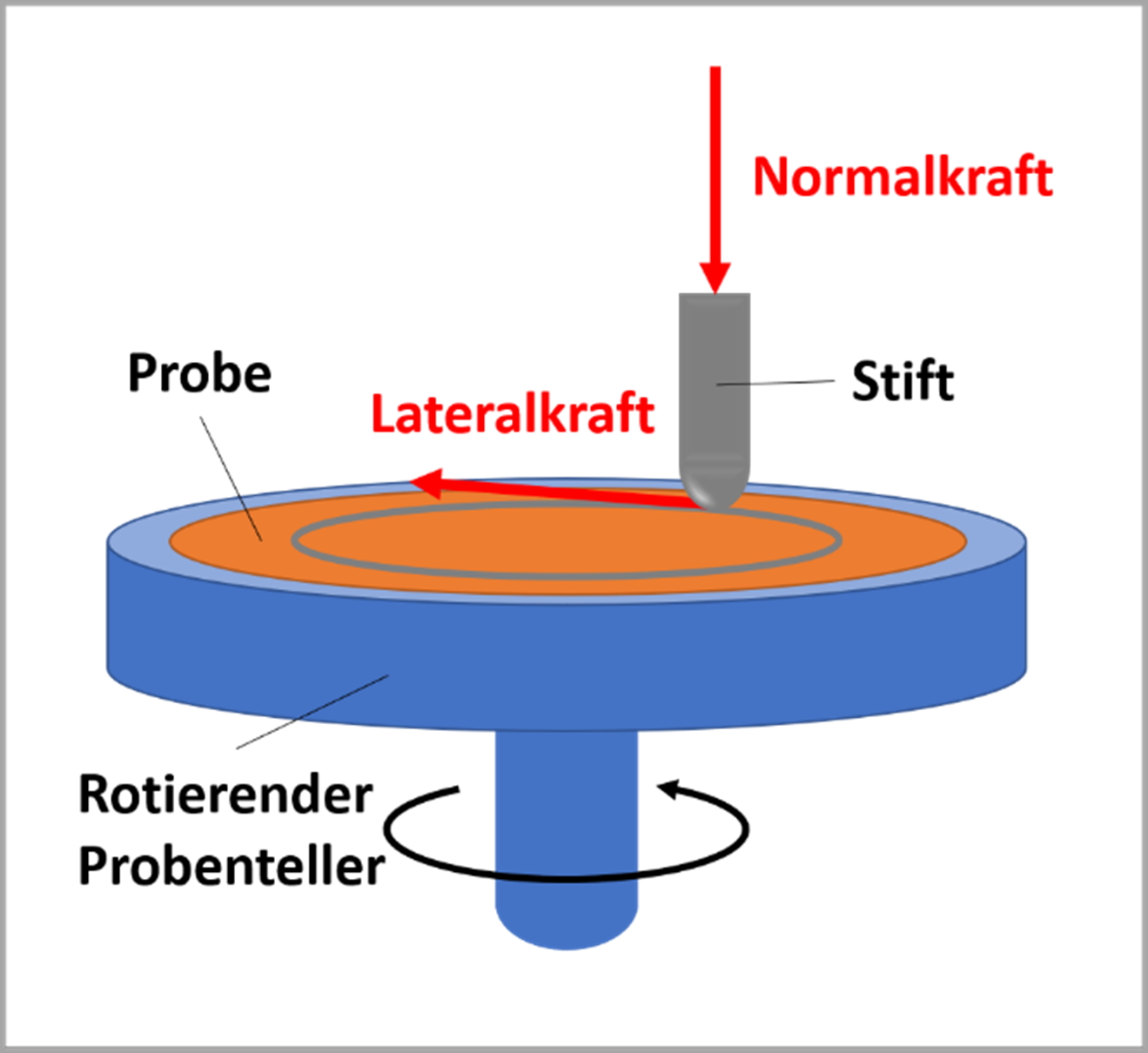

Friction can be measured with a so-called tribometer. The function of a tribometer is comparable to that of a record player. In the latter, a needle scans the structure of the grooves of a record and converts this information into an electrical signal and finally into sound. In the tribometer, a stylus is also in contact with a rotating sample and measures the interaction of the two components. However, the aim of the tribometer is not the sound (although this can certainly be produced by friction), but to measure the forces experienced by the friction pair. In the experiment, the pin presses vertically on the rotating sample with a defined force and one measures the laterally occurring force (lateral force) on the pin, which is caused by the sample moving under the pin (see Fig. 1). The ratio of these two forces enables a conclusion to be drawn about the friction behaviour.

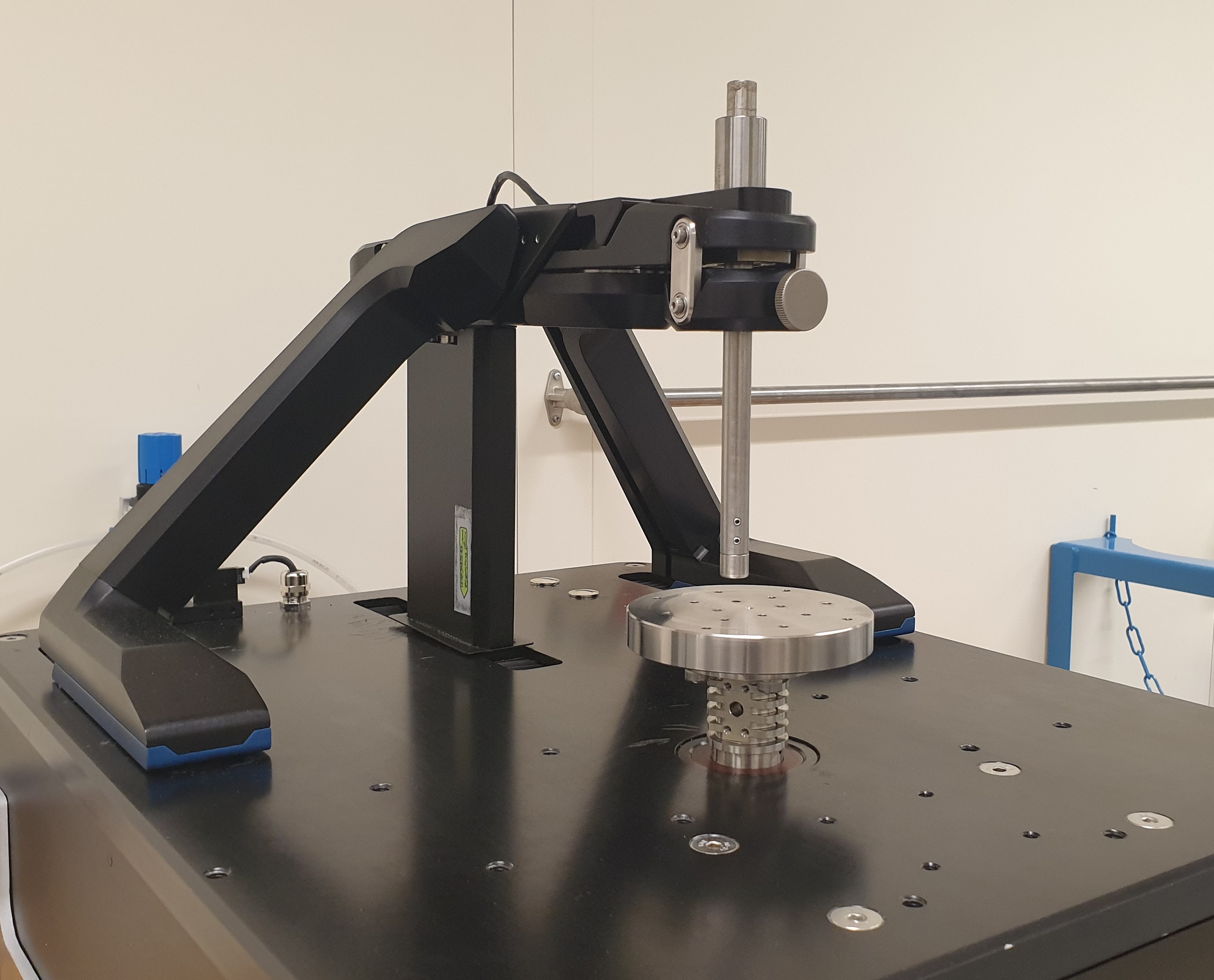

Our laboratory has recently been equipped with a tribometer of the latest generation, the Nanovea T100 model, which the Institute of Polymer Nanotechnology (INKA) purchased together with the Institute of Polymer Technology (IKT) and the Institute for Product and Production Engineering (IPPE). This differs from conventional tribometers in that the load applied to the sample is not generated by weight disks but by a pneumatic device. This allows more precise control over the effective load applied. Loads from 0.5 to 100 N can be applied and the sample table can be rotated at up to 5000 revolutions per minute. Also, straight lines can be run with a linear module and scratch tests can be performed with a diamond tip.

Current projects include the investigation of how structured surfaces influence the friction behaviour of soft plastics, or abrasion tests with shoe soles made of recycled plastic. We are happy to support you with specific questions in the context of tribology.