Institute of Polymer Nanotechnology

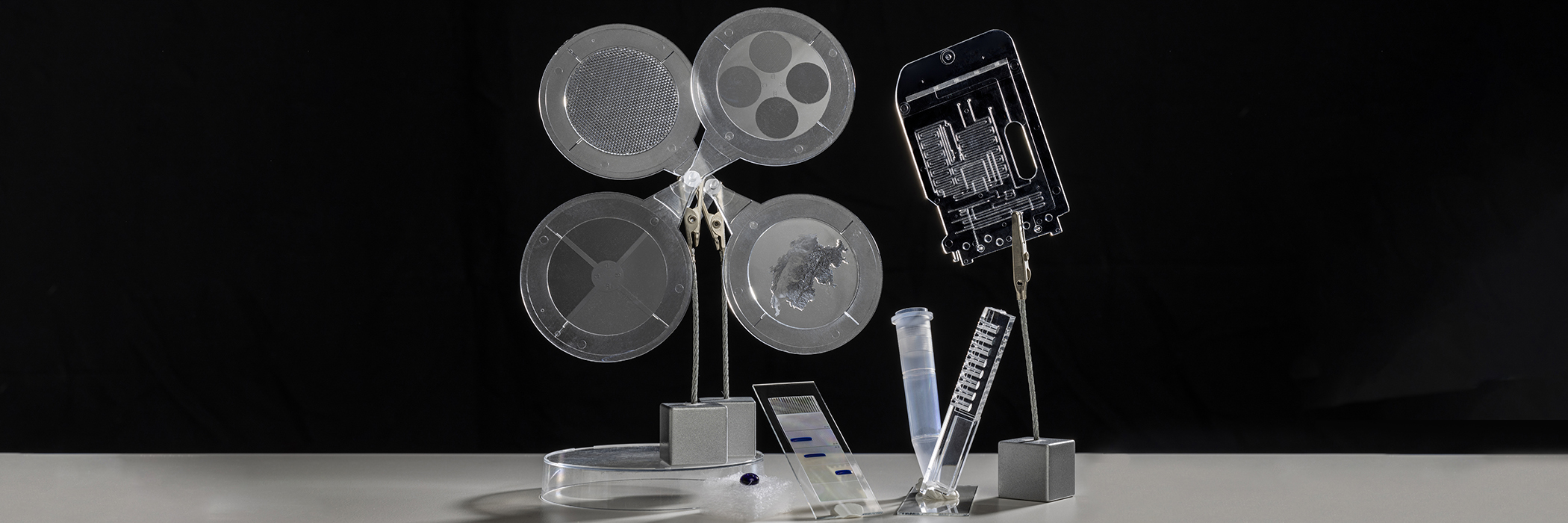

Customized functional surfaces for innovative plastic products

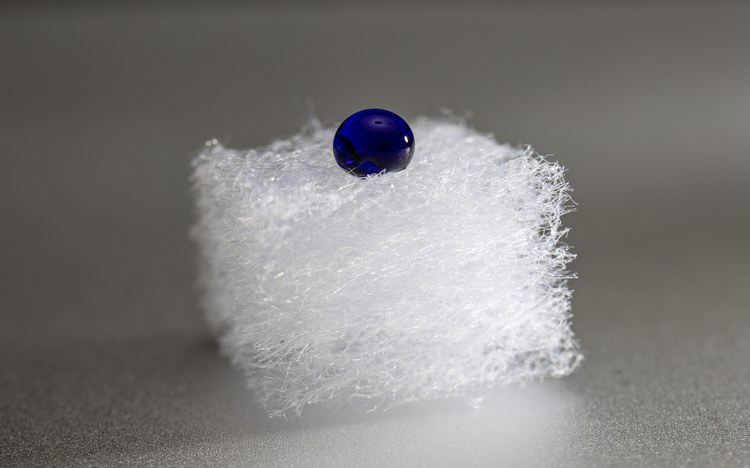

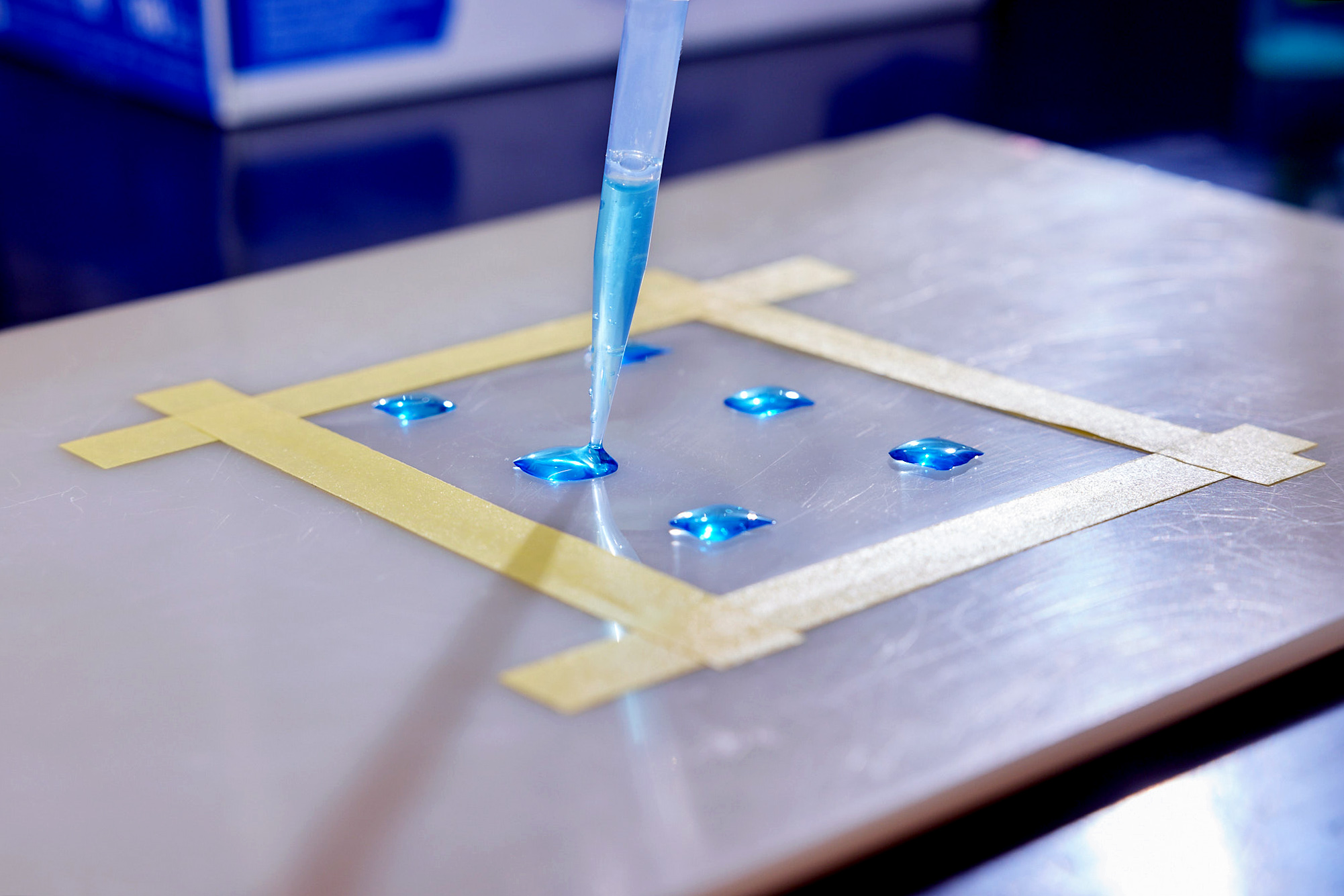

We modify the surface of polymers to provide them with additional functionalities. This is achieved through structuring on the micro and nano scale, by chemical modification or application of coatings, whereby we create additional added value for your polymer products.

We are an interdisciplinary institute at the interface between polymer technology, materials science, mechanical engineering and nanotechnology. Together with partners from industry and academia, our broadly based team develops innovative solutions in the field of materials processes and applications for functional polymer surfaces. We work closely together with the the FHNW Institute of Polymer Engineering.

The quality and performance of the functionalized polymer surfaces are determined with the help of state-of-the-art surface analysis. If required, we also develop our own test methods for the validation of specific functionalities.

We offer our competences both in the context of applied research and development projects (publicly funded or directly financed) as well as in the form of services. Another possibility for cooperation are student projects.

In order to realize your projects in the best possible way, we draw on development partners from the different institutes of the FHNW as well as from our large network in academic institutions and industry.