Surface texturing

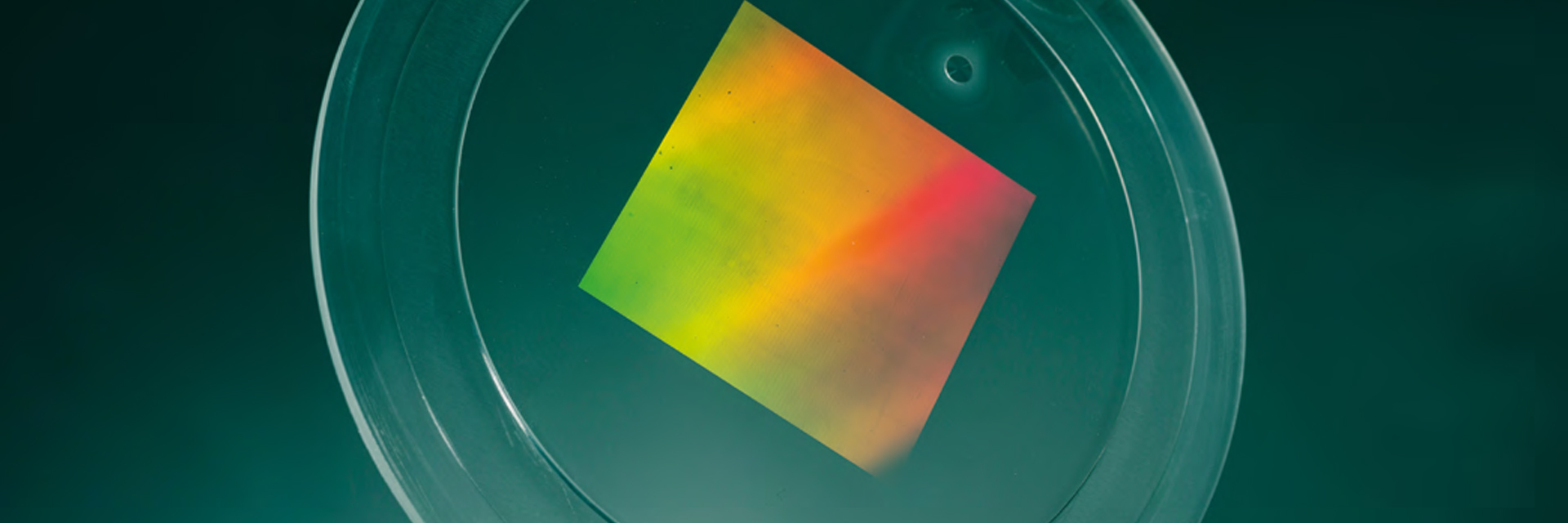

Using micro- and nanostructures, we modify the properties of polymer surfaces without changing their composition.

For this purpose, we develop tools and processes for high fidelity replication of functional surface structures:

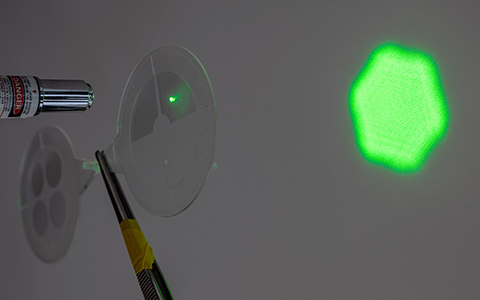

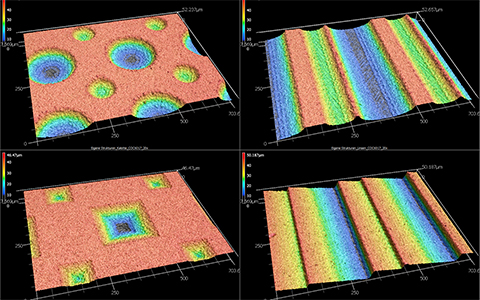

- Design and layout of functional surface topographies (biomimetics, calculations, simulation).

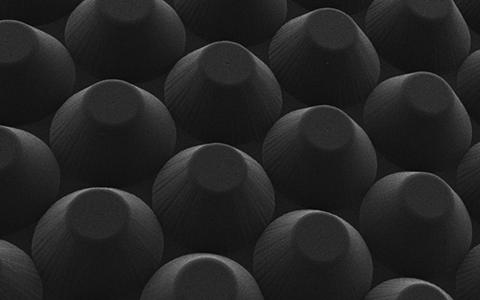

- Fabrication of master structures by ultra-short pulse laser micromachining or lithography

- Tool design and master integration

- Component design and process simulation

- Industrial replication technologies: injection (compression) molding, hot embossing, UV imprinting

- Validation of functional samples