Micro-structures for security

Researchers from the University of Applied Sciences FHNW, the Paul Scherrer Institute PSI and Gemalto AG are developing a new manufacturing process for security elements on identity documents.

Documents like passports, credit cards and driver's licences accompany us in our wallets every day without us realising how sophisticated are. Such personalised identity documents are equipped with a wide variety of security elements to prevent them from being forged or at least to make them much more difficult to forge.

Among other things, different structures are specifically introduced onto the surface by means of embossing processes. The embossing plates required for this are currently very complex and cost-intensive to produce and do not always achieve the desired surface quality.

This is why researchers from the FHNW School of Engineering, the Paul Scherrer Institute PSI and the company Gemalto AG want to develop a new manufacturing process for security elements on identity documents. The Nano-Argovia project LASTRUPOL aims to produce three-dimensional optical structures with high precision and surface quality in a process that is as economical as possible.

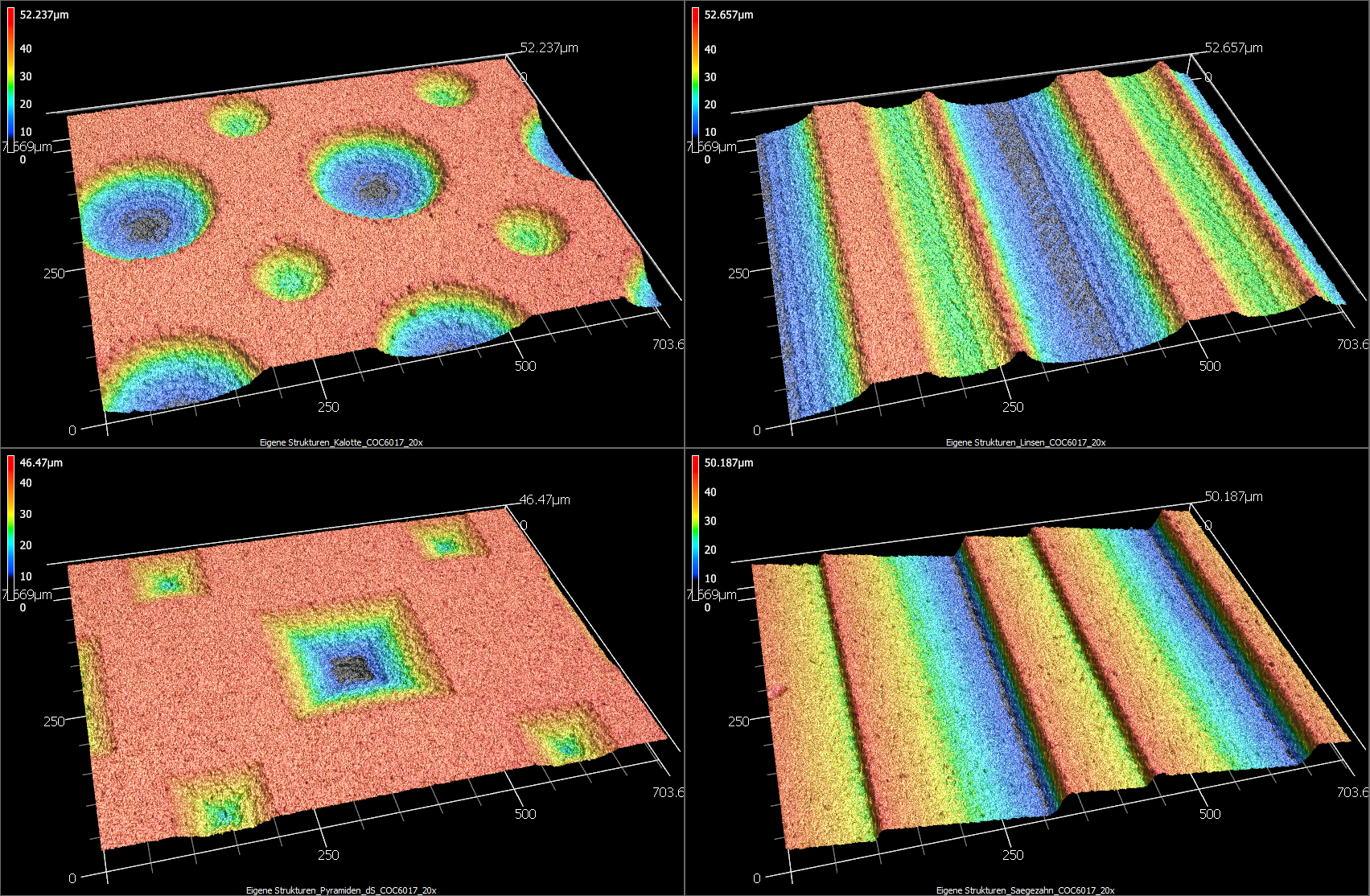

Initial structuring is done with the help of ultra-short laser pulses to selectively remove material from a plastic surface to create defined microstructures. Due to the process, these structures have irregularities and high roughness values, which is why they are smoothened in a further step.

A non-contact method originally developed at PSI for applications in micro-optics is used for this purpose. In this process, the glass transition temperature (the temperature at which the polymers change from a solid state to a viscous melt) is selectively reduced at the surface. If the sample is gently heated after this pre-treatment, only the treated top layer softens and is thus smoothened out. The underlying structure and deeper layers remain unchanged.

In the LASTRUPOL project, this two-step process must be adapted to new materials and significantly larger structures. This project, which seems simple at first glance, presents a particularly great challenge that must be mastered with material science skills.

By combining the two techniques, the aim is to efficiently produce embossing plates for the reproduction of different security elements. The initial focus is on two different types of security elements: on one hand, optical elements that appear due to different light diffraction at the structures and on the other hand, optical elements that appear through tiny lenticular and spherical plastic lenses.

For Gemalto, the project has great significance: "We are a leading company in the field of digital and physical identity solutions," explains Dr Christian Sailer, Head of Physical Document Security R&D Switzerland at Gemalto, "it is essential for us to invest in new technologies for the production of security products in order to maintain this leading role. The Nano-Argovia project LASTRUPOL offers an excellent opportunity to benefit from the know-how of the experts in the field of plastics processing at the School of Engineering and the PSI".