Polymer Processing and Sustainability

We conceive product and procedure innovations and develop them until they are ready for the market, focussing in particular on high-performance polymers and composites.

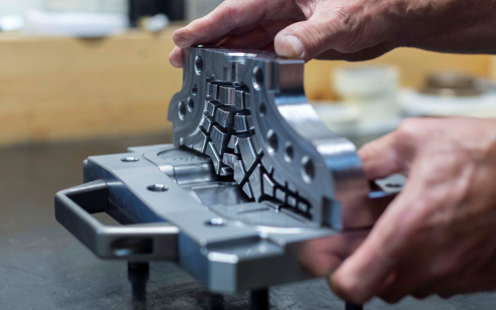

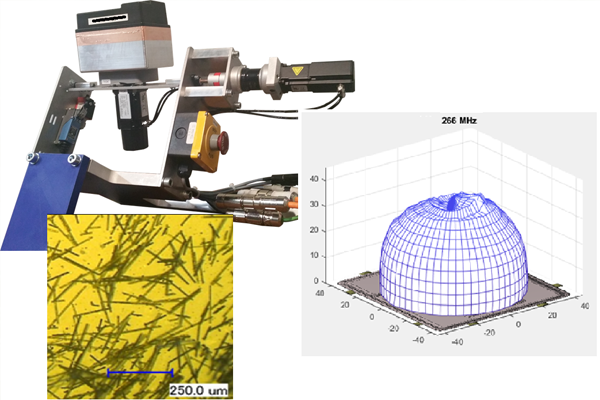

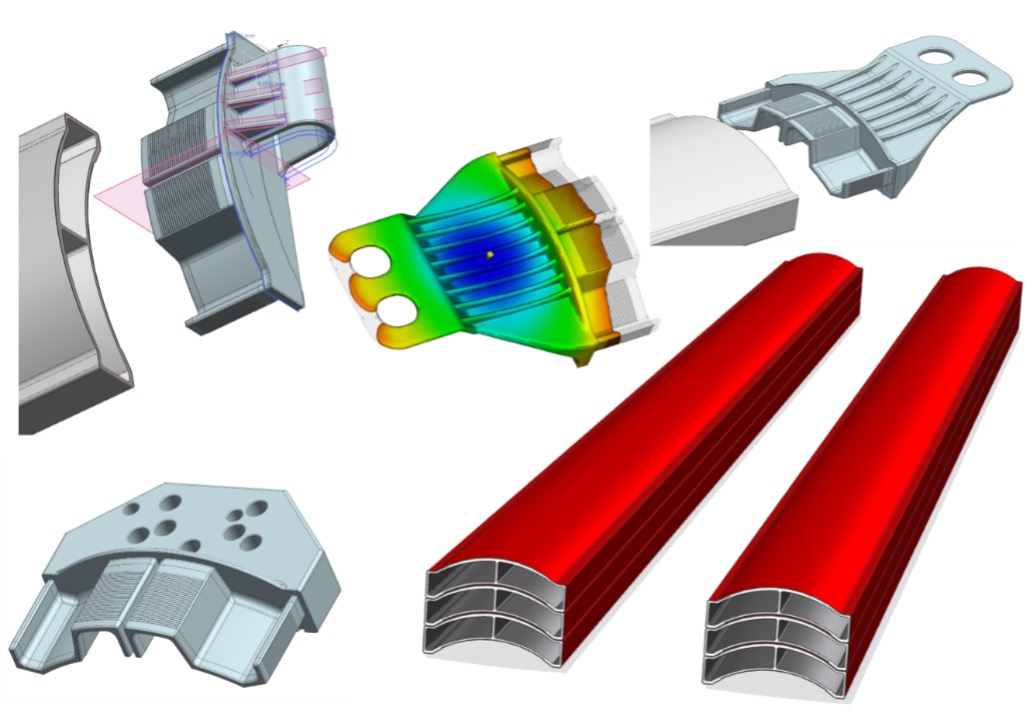

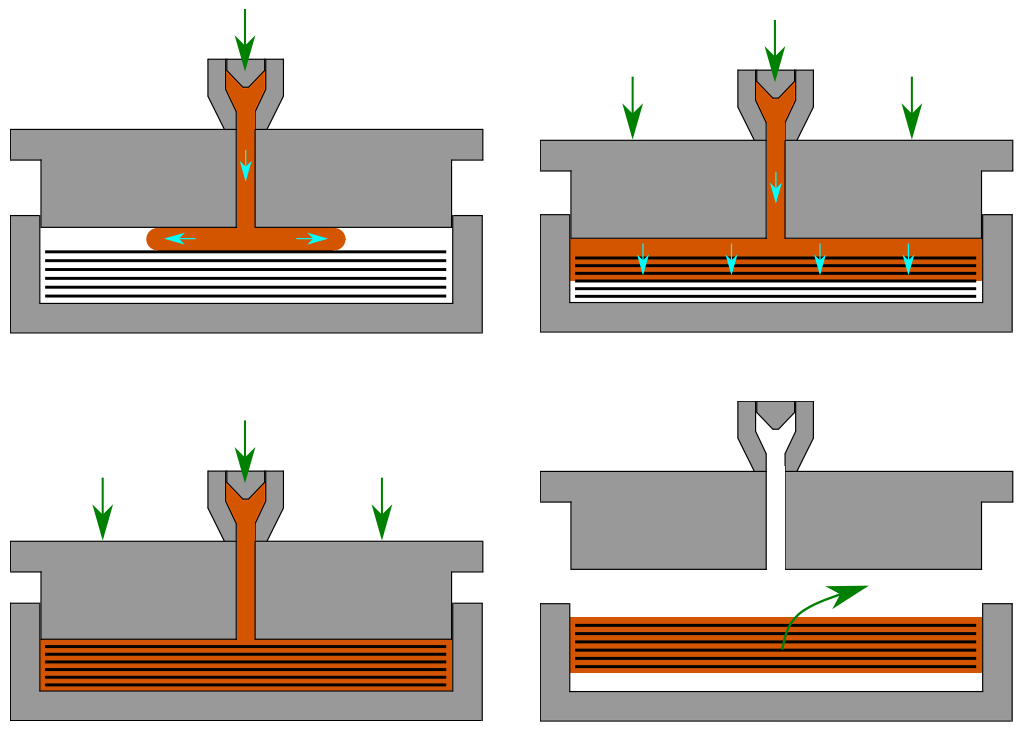

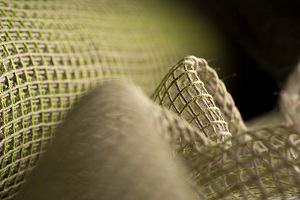

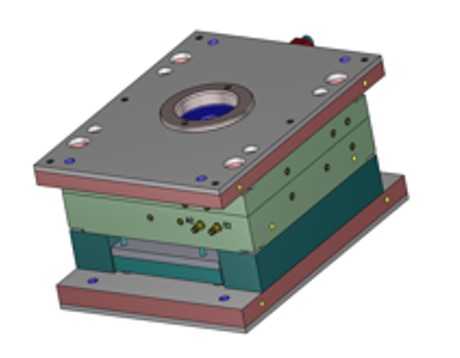

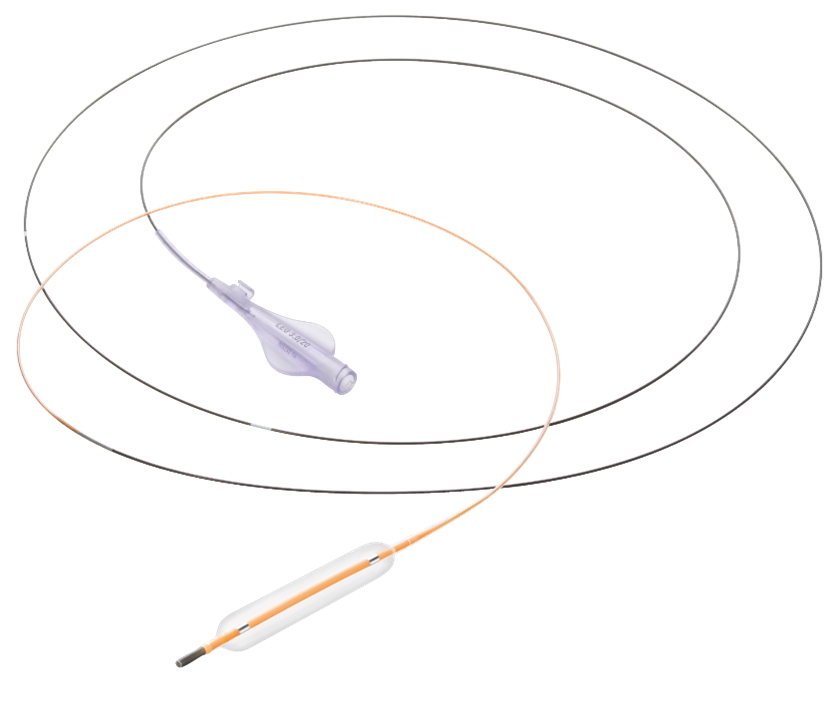

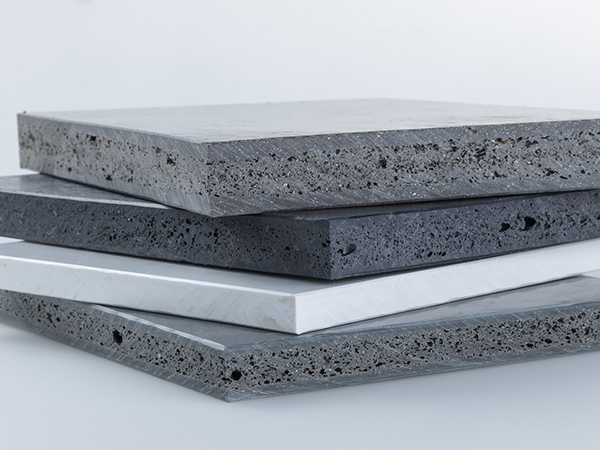

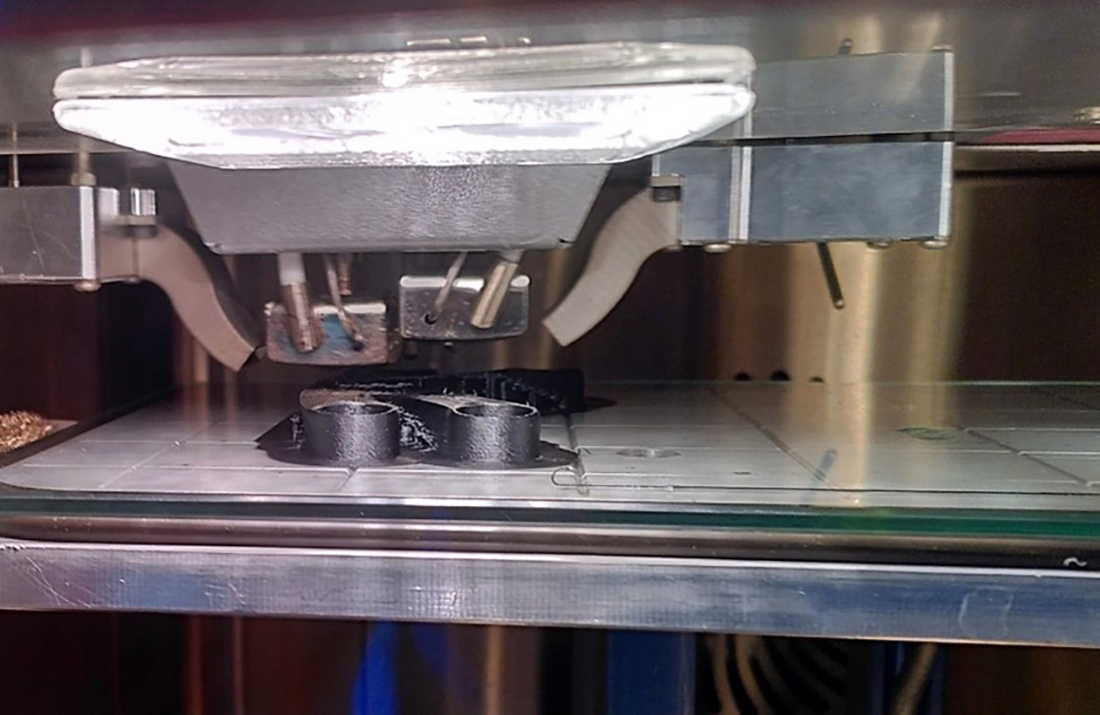

The interplay of material development, process engineering, tool construction and the precise control of critical processing parameters forms the basis of every procedural innovation. We achieve this goal due to the synergy between the numerical and experimental methods we carry out at our extensive pilot plant where we fuse nanotechnology together with conventional polymer engineering and composite technology. Whether you would like to convert natural fibres into high-performance composites, take pultrusion, extrusion or sheathing processes to extremes, produce high-performance composites on an injection moulding machine, manufacture innovative compounds, integrate functional structures (see the surface structuring group at the Institute of Polymer Nanotechnology) or help discontinuous fibre architectures achieve an industrial breakthrough, we have just the right expert for you.