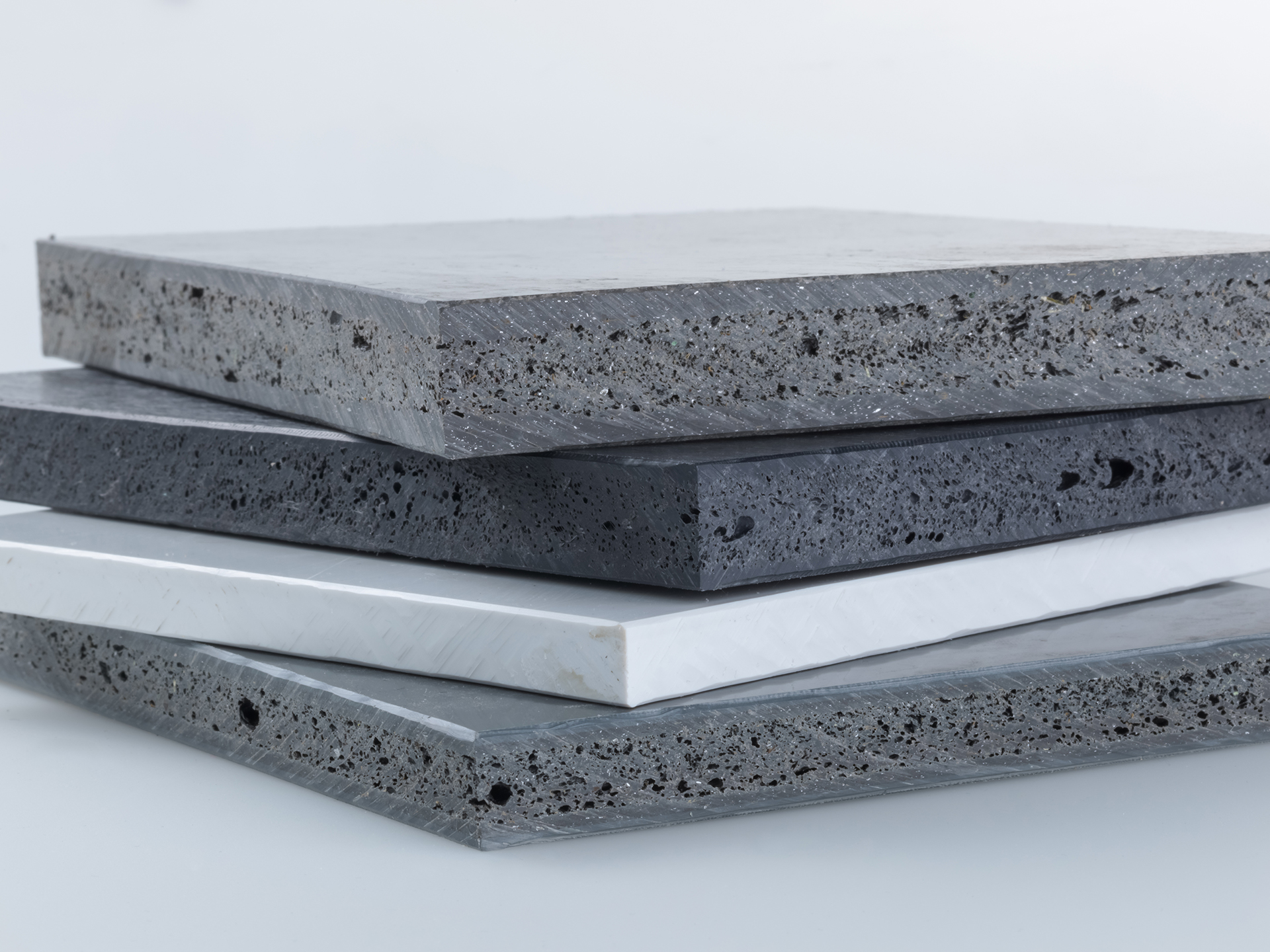

Foamed sandwich panels made of recycled mixed plastic

Together with UpBoards GmbH, recycled foamed sandwich panels made of mixed plastic were developed, including an efficient manufacturing process.

- Circular economy

- Recycling

- Sandwich panels

- Foaming

- Mixed plastic

To increase the reuse of mixed plastic waste from side streams that are difficult to recycle, and which are mostly incinerated in Switzerland, UpBoards has searched for an innovative and recyclable solution. The solution is based on a recycled board that can be used for furniture and formwork construction. The manufacturing process had to be energy and economically efficient.

The aim of the project was to develop and produce recycled sandwich panels from mixed plastic waste with different stiffness and constant panel properties. The panels should be an ecologically and economically interesting alternative to MDF and shuttering panels. Four different qualities were defined at the beginning. In addition, a stable process was to be developed to manufacture the boards.

Four different sheet qualities were developed. Cover layers with reinforcing materials were extruded and mixed plastic was foamed in the core. The foaming of the mixed plastic proved to be particularly challenging, as the material contains impurities such as cardboard, paper, aluminium or wood. On the other hand, the mixed plastic is supplied in the form of small pieces of film, which makes gas absorption more difficult.

With the help of simulations and simple tests, a process to produce the sandwich panels was developed and a test plant was set up. Major challenges were the warpage, the adhesion of the cover layers to the mold or the core, the foaming over the entire filling distance or the sealing. The fluctuating material behavior of the mixed plastic plays a major role here.

In addition, a life cycle assessment was carried out. This showed that the panels with recycled material have a significantly lower CO2 impact than panels with virgin material.

Client | |

Execution | |

Duration | 18 months |

Förderung | |

Project team | Institute of Polymer Engineering FHNW: Simone Battaglia, Mariona Diaz, Oskar Häfeli, Philipp Krzikalla, Alex Massenbauer, Prof. Jürg De Pietro, Halime Philipp, Prof. Dr. Christian Rytka, Moritz Thommen, Stephanie Wegmann, Daniel Zürcher UpBoards GmbH: Raphael Markstaller, Joel Mathew, Urs Ebneter, Damir Sulejmanovski |