Thermoplastic Thin-Ply Tapes as a Key Technology for Lightweight Liquid Hydrogen Tanks

The use of hydrogen as an energy carrier plays a key role in the successful energy transition. For the safe and efficient transport of hydrogen, new materials are required that are both lightweight and high-strength while withstanding extreme temperatures. The research project LeiWaCo (Lightweight Hydrogen Container), in collaboration with the industrial partner Suprem SA and in association with the German BMBF research project of the same name, is developing innovative thermoplastic fiber-reinforced composites for use in cryogenic hydrogen tanks. The aim is to produce a lightweight, tight, and cost-efficient tank material that meets the stringent requirements of hydrogen mobility.

Initial Situation

Hydrogen is considered a central energy carrier of the future, particularly in heavy transport, aviation, and maritime applications. However, storage in liquid form requires extremely low temperatures. Conventional aluminum or steel tanks are heavy, energy-intensive to manufacture, and lose tightness after repeated cryogenic cycles.

Fiber-reinforced composites promise significant weight savings but exhibit microcracking at cryogenic temperatures. These cracks arise from differences in thermal expansion between fiber and matrix and jeopardize the tightness of the tank.

LeiWaCo addresses this challenge by using high-performance thermoplastic materials based on PAEK (e.g., PEEK, PEKK) in combination with thin-layer laminates (thin-ply technology). These material systems are characterized by high toughness, temperature resistance, and excellent reprocessability, enabling a fully recyclable, CO₂-efficient lightweight solution.

Objectives

LeiWaCo aims to develop a production-ready, lightweight, and sustainable tank material for liquid hydrogen.

The key development objectives are:

Material development: Selection and characterization of PAEK-based thermoplastics and carbon fibers with optimal performance at −253 °C.

Process technology: Development of thermoplastic thin-ply tapes using tow-spreading technology to produce ultra-thin, uniform fiber tapes.

Manufacturing & consolidation: Establishment of a filament winding process for the precise production of cryogenic structures with integrated in-situ consolidation.

Validation: Verification of tightness, mechanical stability, and long-term durability under cryogenic conditions.

Sustainability: Use of recyclable materials and energy-efficient manufacturing processes to significantly reduce the CO₂ footprint of tank production.

These innovations lay the foundation for the industrial production of lightweight, safe, and recyclable hydrogen tanks for use in aviation, maritime transport, and heavy-duty vehicles.

Results

During the project period, significant scientific and technological progress was achieved:

Material characterization: Three PAEK polymers (PEEK, PEKK, LM-PAEK) were investigated with regard to their mechanical and thermal properties. PEKK showed 20% higher fiber–matrix adhesion and better processability at low temperatures.

Fiber analysis: Various carbon fibers (e.g., Tenax-E HTS45, IM7, AS4) were evaluated. AS4-12K and IM7 proved particularly suitable for thermoplastic matrix systems.

Experimental testing: Numerous material tests—including tensile, shear, and bending tests as well as gas permeability measurements—confirmed the suitability of the developed systems for cryogenic applications.

Tow-spreading technology: FHNW supported its project partner Suprem in the development of thin plies using tow-spreading technology to achieve improved tape impregnation.

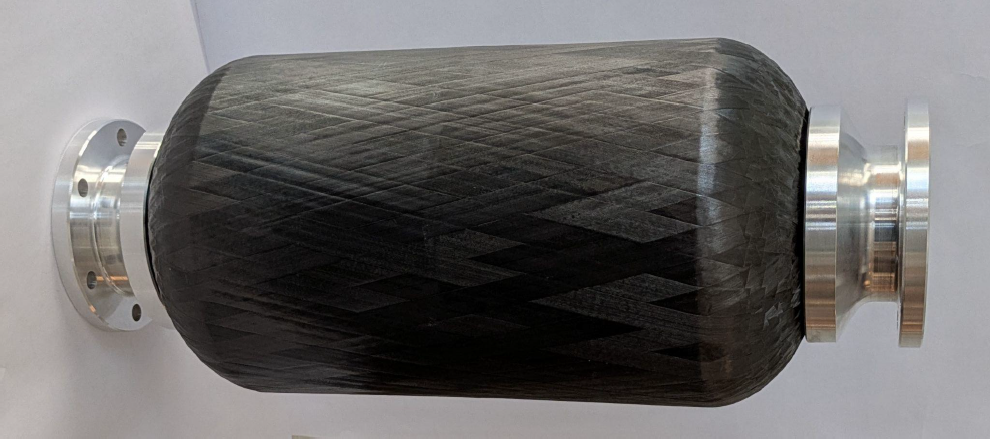

Winding process: Initial trials on the FHNW filament winding system demonstrated good processability of the new materials at 360–380 °C and resulted in dense, crack-free structures.

These results demonstrate the technical feasibility of thin-ply technology for cryogenic applications and provide a solid basis for industrial implementation.

In the next phase, the production of thin-ply tapes at FHNW will be further investigated, and the filament winding process will be optimized for complex geometries. In addition, demonstrator tanks will be manufactured and tested under real cryogenic conditions.

The findings will feed directly into the development of lightweight hydrogen tanks for aircraft, ships, and commercial vehicles. By using recyclable thermoplastics and automated manufacturing processes, CO₂ emissions during production and operation can be significantly reduced.

With its groundbreaking material development for hydrogen tanks, LeiWaCo won the JEC Innovation Award 2026 and stands as an exemplary case of successful transfer from research to sustainable industrial applications.

Projekt-Information

Client | |

Implementation | |

Duration | 3 years |

Funding | |

Team | Julian Kupski (Projektleiter), Christian Brauner |