Drives Fleet Performance Optimization

The project aims to optimize the performance, efficiency and reliability of industrial MV drives through advanced analysis, design, control and estimation methods.

Technologies

- Data driven control design

- System Identification

- Signal processing

- Optimization

Background

As of 2022 industrial power electronic drives are present in nearly all energy, industry and mobility sectors with an estimated market size of more than 17 Billion USD, enabling high level power condition and adaptation to process needs at good energy efficiency over a wide range of power demands.

One main limitation of the current operation of MV drives are the interacting control loops calibrated for a single operating condition that, in the new dynamic scenario, leads at best to reduced system performance and in the worst-case system instability.

Operating the drive efficiently and reliably across the whole lifecycle in a complex and unpredictable scenarios, requires advanced analysis, design, control and estimation methods.

Goals

Optimal operation of industrial MV drives to maximize the performance of the modern power conversion system by improving efficiency, reliability, and safety, over the complete system lifecycle.

Specifically the project will be addressing the following:

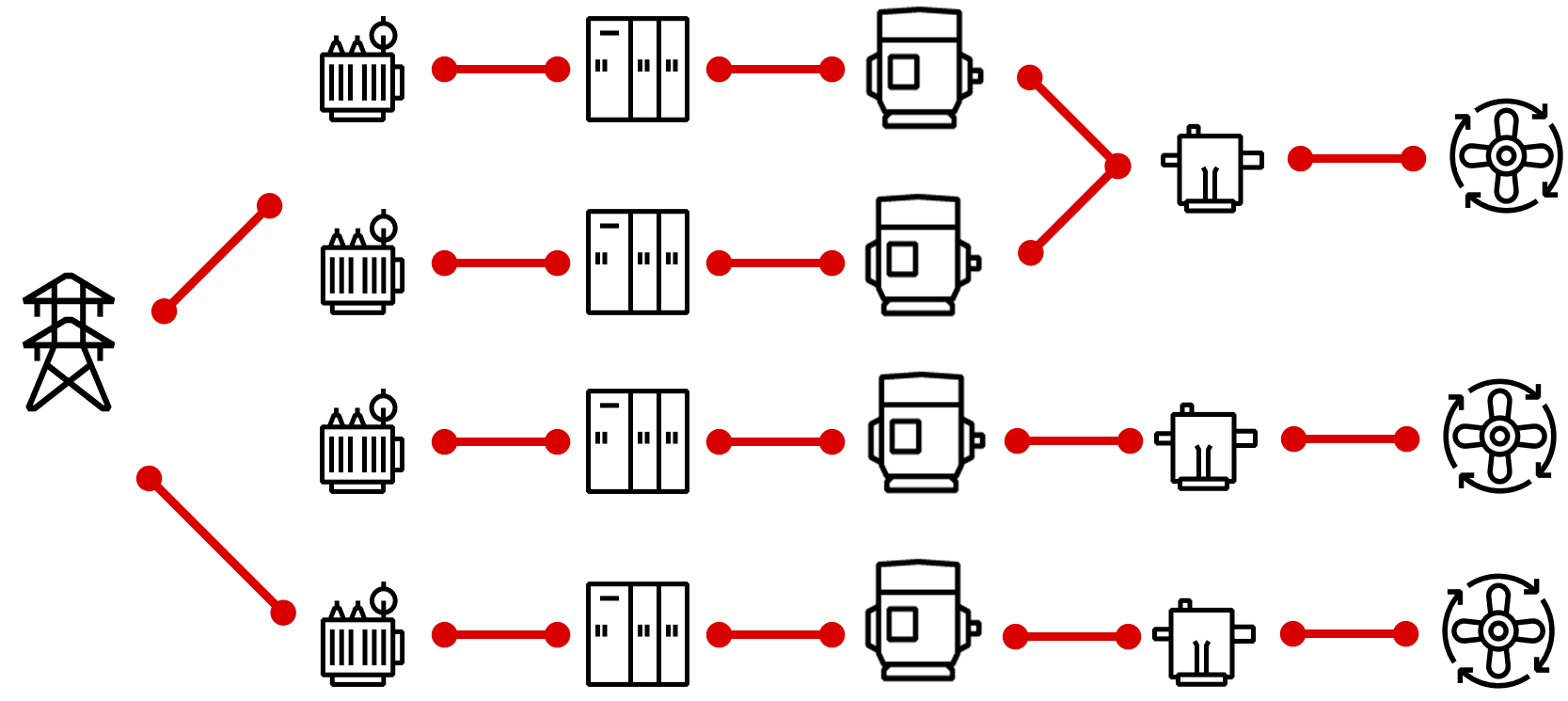

- Interoperability requirements: including stability of the various segments from grid to process

- Drives fleet performance coordination: optimal exchange of power with constraints of the process and supply has to be considered at the control design level.

- Process performance optimization: Processes need to satisfy surge conditions. Supply partial power during grid transient conditions is of paramount importance to keep the process in till the transient conditions are cleared.

Project information

Client | |

Execution | FHNW School of Engineering |

Project team | FHNW Institute of Electric Power Systems |

Duration | 2 Years. February 2023 to February 2025 |

Funding | |

Project lead |