Machine Learning Approach for Induction Motor Parameter Estimation

A novel method was developed that enables the reliable determination of the electrical motor parameters through the use of machine learning.

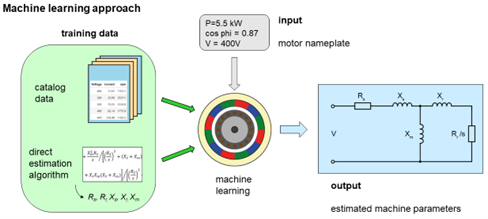

The electrical simulation of induction motors, for example in the Typhoon HIL Control Center, requires knowledge of the electrical parameters of its equivalent circuit. Datasheets do not provide these data directly, but various methods exist to estimate the parameters from the available catalog data. In a previous project, we implemented a method that directly calculates motor parameters from full catalog data. Within this project, we use machine learning to estimate the motor parameters for cases in which only data from the motor nameplate are known.

- Development of a procedure for the parameter estimation of induction motors from nameplate data

- Usage of machine learning trained with catalog data from various manufacturers

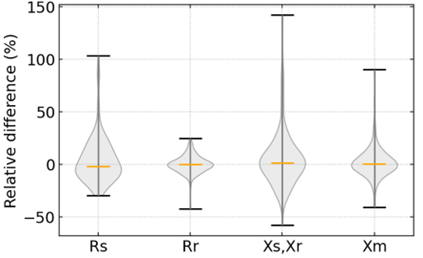

- Identify the most suitable estimation algorithm based on a training/test data cross correlation analysis

Several machine learning based regression methods for the parameter estimation of induction machines have been investigated and implemented in Python. Machine learning algorithms bring a clear advantage to the parameter estimation problem: one can freely choose the set of known machine parameters and get a useful estimate for the electrical parameters. Thus, it is possible to get a result from only a very limited number of input parameters, as for example the values printed on the motor nameplate.

Client | |

Execution | |

Duration | 6 months, from March to August 2022 |

Funding | Hightech Zentrum Aargau AG, Peter Morf and Beat Dobmann |

Project team | Christian Stamm, Georg Traxler-Samek (FHNW) |