Microplastic detecion in water samples

The increasing microplastic pollution in air, water and soil requires the development of robust and sensitive analytical methods to better understand and address the problem. Plastics are cheap, stable and corrosion resistant, making this class of materials attractive for many applications. Plastics consist of long chains of polymer molecules made from organic and inorganic raw materials derived from mineral oil, coal and natural gas. Through physical or chemical decomposition, they break down to microscopically small particles that are distributed in the air, water and soil. Due to their composition, microplastics are also partially resistant to decomposition.

Microplastics are categorized into macro-, micro- and nanoplastics. Microplastics can be different into primary (release of plastic particles e.g. cosmetics, detergent) and secondary plastics (fragmentation of plastic objects)[4]. Primary microplastics are in microscopic sizes and are typically found in facial cleansers and certain cosmetics. They are marketed as “microbeads” or “microexfoliates” made from polyethylene and polypropylene to remove dead cells from the skin. Secondary microplastics are created by the degradation and subsequent fragmentation of larger plastic parts. This decomposition is caused by prolonged exposure to sunlight or by additives in the plastic. The ultraviolet radiation from sunlight can oxidise the polymer matrix, which leads to photodegradation. Physical factors such as the abrasion of car tyres emit tyre wear particles (TWP), which account for at least 11% of the PM10 concentration (dust particles with a diameter of less than 10 micrometres [1]) on a busy road in Switzerland. Due to methodological limitations in the measurement of the PM 2.5 fraction, this proportion could still be underestimated [2]. In urban areas, fine dust matter accounts for 16-41 % of road dust [3].

Microplastics are harmful to human health. This is shown, for example, by respiratory complaints among workers in textile, flock and vinyl chloride (VC) or polyvinyl chloride (PVC) factories [4]. Microplastics also contain additives, some of which are hazardous to the environment and human health. In addition, due to the larger surface area, harmful chemicals such as polycyclic aromatic hydrocarbons (PAHs) can easily accumulate on the surface [5]. To date, there have only been a few studies on the health effects of microplastics. The University of Applied Sciences and Arts Northwestern Switzerland (FHNW) is therefore setting up a competence centre to develop suitable methods for the detection of microplastics in various environmental matrices. In particular, pyrolysis-gas chromatography coupled with mass spectrometry (Py-GC-MS) is being further developed and compared with established optical methods such as chemical imaging and spectral analysis using LDIR and RAMAN. In comparison to the optical methods, Py-GC-MS provides quantitative information on the microplastics in the sample and is independent of their size or shape.

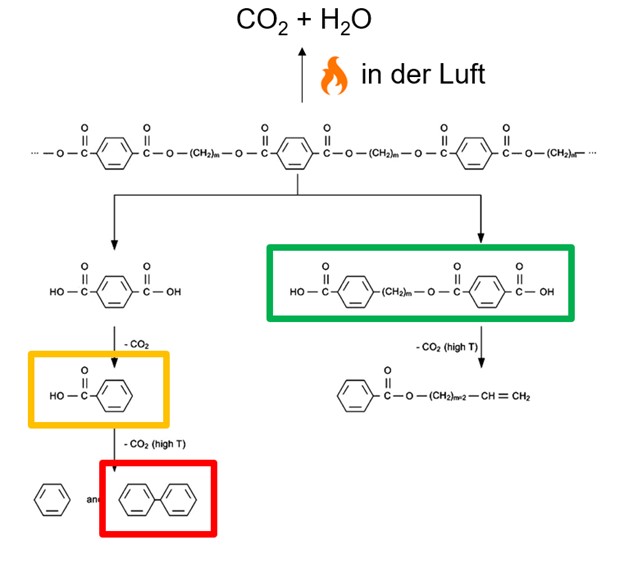

Gas chromatography (GC) separates substances based on different boiling points (vapour pressures) and polarities before they are introduced into the mass spectrometer (MS). In the MS, the substances are first ionised, i.e. charged, so that they can be accelerated electromagnetically through the mass analyser, where they are further separated and detected according to their mass-to-charge ratio. In this way, the molecular masses of the individual components are obtained from the sample previously separated by GC. In addition, certain ions fragment, disintegrate, into fragments, which in turn provides information about their structure. This separation and subsequent mass identification can be used to create databases for simplified sample analysis. So why pyrolysis GC-MS? The reason is simple: every combustion of hydrocarbons produces CO2 and water, which are analytically not suitable. This is why pyrolysis is used, essentially combustion without oxygen, forming specific pyrolysis products of very long-chain plastics, which can be analysed. These are generally categorised into marker peaks (green), ambiguous peaks (orange) and non-specific peaks (red), with the marker peaks being used for identification.

Unfortunately, when we talk about microplastics in water, their analysis is not the only issue. Some types of microplastics have a higher or lower density than water. Hence, some particles are found on the surface of the water and others in the sediment. The research group led by Prof Dr Stefan Gaugler (pictured) is therefore developing a new solution for sampling surface or groundwater specifically and with defined quantities, to be applied in lakes and rivers.

Literatur

[1] „MONET 2030: Feinstaubkonzentrationen | Bundesamt für Statistik“. Zugegriffen: 7. Januar 2024. [Online]. Verfügbar unter: https://www.bfs.admin.ch/bfs/de/home/statistiken/nachhal-tige-entwicklung/monet-2030/alle-nach-themen/3-gesundheit/feinstaub-konzentratio-nen.html

[2] J. Rausch, D. Jaramillo-Vogel, S. Perseguers, N. Schnidrig, B. Grobéty, und P. Yajan, „Au-tomated identification and quantification of tire wear particles (TWP) in airborne dust: SEM/EDX single particle analysis coupled to a machine learning classifier“, Sci. Total Envi-ron., Bd. 803, S. 149832, Jan. 2022, doi: 10.1016/j.scitotenv.2021.149832.

[3] „Modelled atmospheric concentration of tyre wear in an urban environment – ScienceDirect“. Zugegriffen: 11. Dezember 2023. [Online]. Verfügbar unter: https://www.sciencedi-rect.com/science/article/pii/S2590162123000254?pes=vor#bib3

[4] J. C. Prata, „Airborne microplastics: Consequences to human health?“, Environ. Pollut., Bd. 234, S. 115–126, März 2018, doi: 10.1016/j.envpol.2017.11.043.

[5] J. C. Prata, J. P. da Costa, I. Lopes, A. C. Duarte, und T. Rocha-Santos, „Environmental ex-posure to microplastics: An overview on possible human health effects“, Sci. Total Environ., Bd. 702, S. 134455, Feb. 2020, doi: 10.1016/j.scitotenv.2019.134455.

[6] Brems, A., Baeyens, J., Vandecasteele, C., & Dewil, R., Polymeric Cracking of Waste Polyethylene Terephthalate to Chemicals and Energy. Journal of the Air & Waste Management Association, 2011, 61(7), 721–731