Material characterisation

A comprehensive infrastructure allows us to directly understand the various aspects of construction and processing and to analyse the interaction of material properties and their effects in detail.

Rheology

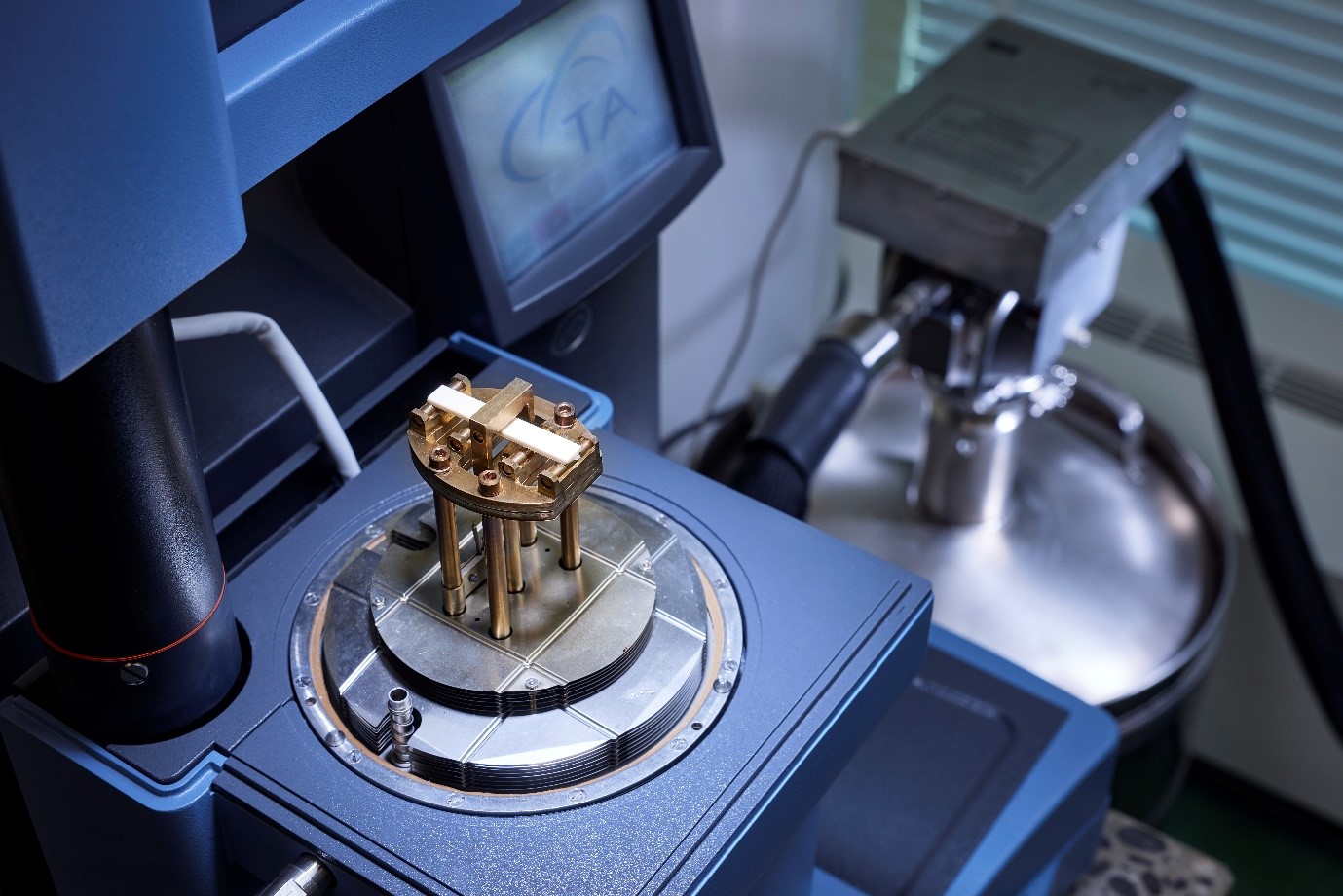

Plate-plate / cone-plate

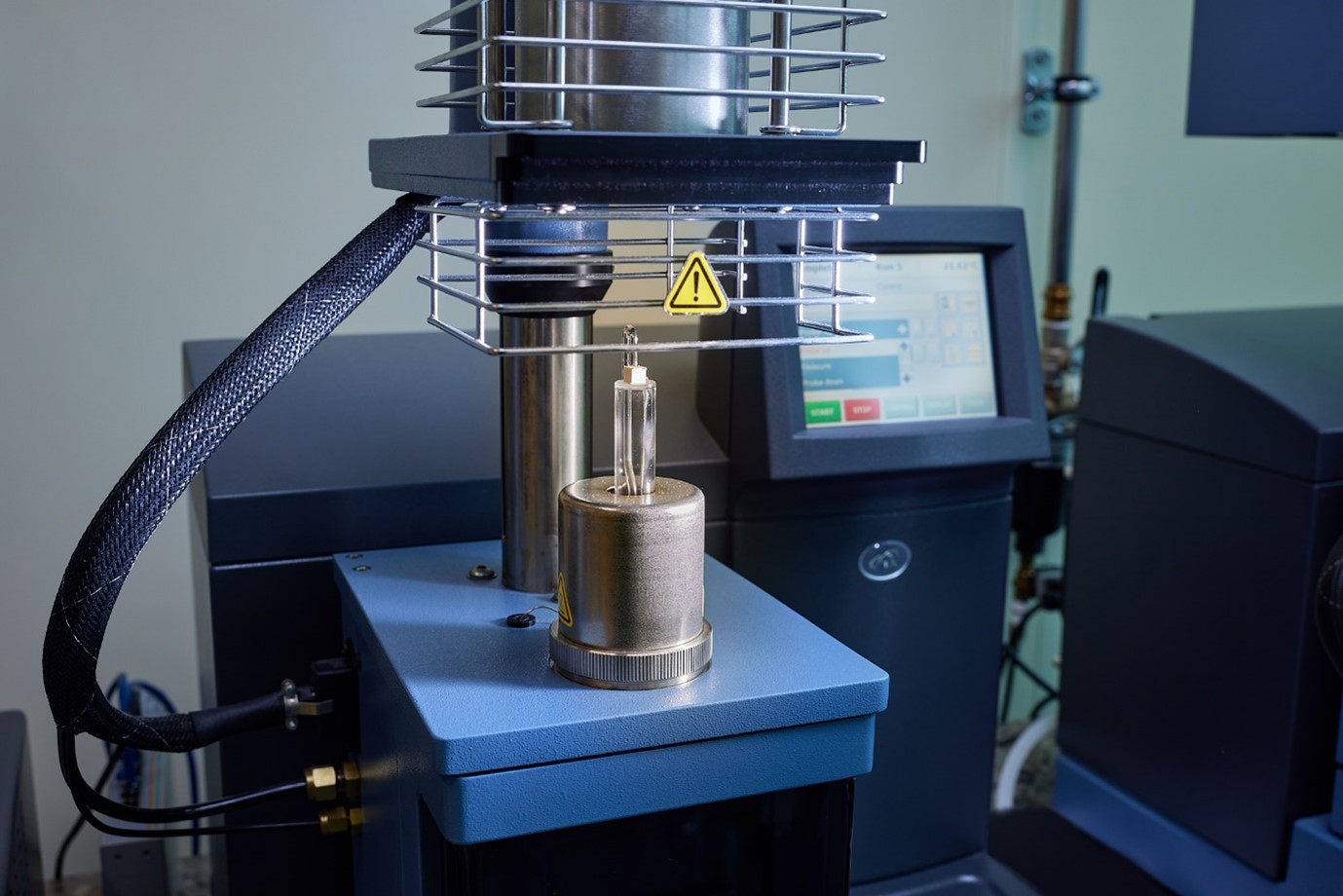

Capillary rheometer incl. rheotens and pVT

Melt index tester (MFI)

Light microscopy

Accessories: Heating table & micro tensile tester

Water content determination

Ultrasonic testing for composite materials

Creep test bench with temperature chamber

Climatic chamber (-10 - 100 °C; 10 - 98 % r.h.)

Colour, gloss, density, hardness, pH, conductivity, stress crack resistance

Corrosion resistance Potentiostat / Galvanostat PGSTAT101

Component and fibre orientation measurement APODIUS Vision System 3D