Product development

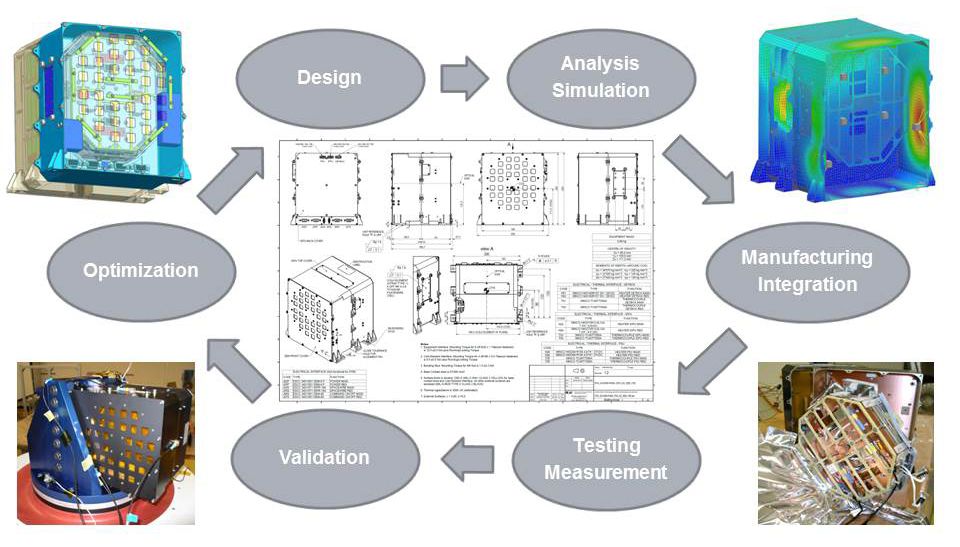

We support our customers through the entire product development cycle with the process steps of design, simulation and production.

The Institute of Product and Production Engineering always views the product development cycle, with the process steps of design, simulation and production, as a whole.

The Institute has experience with the entire cycle and, if required, can execute this in full. It also works in partnership with customers and partners who require support during one or more process steps.

Product development is the heart of a healthy company, because technological advancement is continuously moving forward. Keeping step is therefore necessary for a company to survive, and a role as a technological leader guarantees economic success. The new and further development of products is nothing other than the translation of this advancement into a company's product portfolio.