ECPE Joint Research Programme: Reliability comparison of Si IGBTs and SiC MOSFETs for e-mobility applications

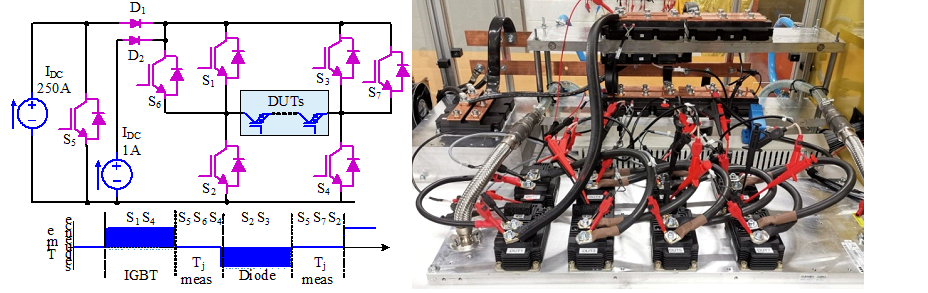

A new reliability test method that stresses both, transistor and diode is applied to obtain representative reliability data for e-mobility applications. A direct comparison between a two-chip technology such as IGBT/diode and single-chip technology such as MOSFETs with the same package and tested under the same conditions is possible.

An Electric Vehicle’s (EV) powertrain operates as inverter when feeding the motor from the battery (accelerating), and as rectifier when recuperating back into the battery (braking). When e.g. a typical 2-level, 3-phase active rectifier/inverter operates in inverter mode, the transistors operate at higher temperatures than the diodes due to a higher average current. In rectifier operation, the diodes carry more current than the transistors and thus experience a higher thermal stress. Single-chip (MOSFETs) and two-chip technologies (IGBT/diode) will result in different load profiles and different junction temperature swings, which play an important role on the device reliability.

- E-mobility electrical simulation using realistic mission profiles: single-chip vs. two-chip technologies

- Validation of bidirectional power cycling test bench

- Bidirectional power cycling tests by stressing both transistor and diode

- Reliability evaluation of SiC MOSFETs and Si IGBTs for a e-mobility application

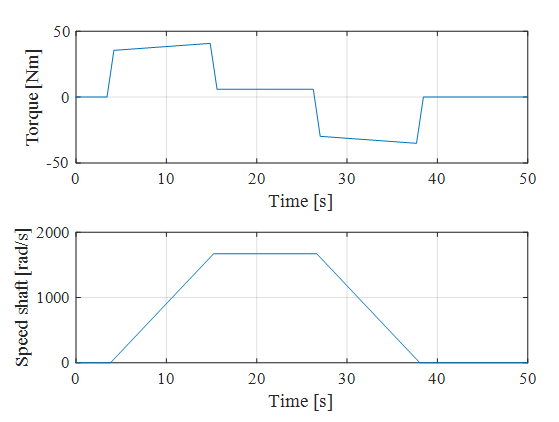

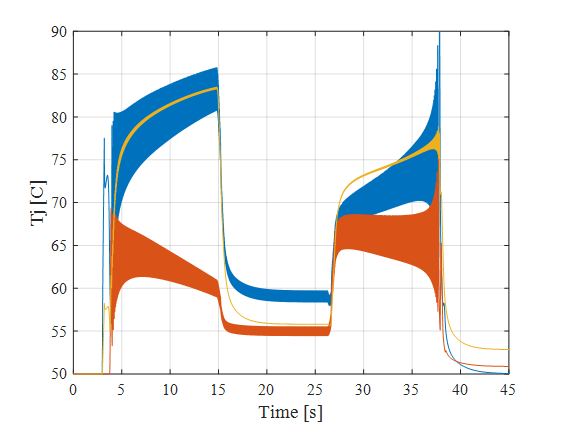

First, a reliability study of power semiconductor devices in an Electric Vehicle application is performed, based on a driving cycle mission profile. A simple mission profile (Fig. 2) with the speed of the car (km/h) is converted into the torque and speed of the motor shaft, which is the input mission profile to an electrical simulation containing the electro-thermal models and datasheet parameters of the power semiconductor devices. As a result, the loading of the transistor/diode can be computed for the two topologies: single-chip (Si IGBT) and two-chip configurations (SiC MOSFET). The thermal behavior for the given mission profile is shown in Fig. 3, where it can be observed that:

- Two-chip configurations (Si IGBT) have two thermal stresses: (i) motor frequency variations and (ii) mission profile variations.

- Single-chip configurations (SiC MOSFET) have only one thermal stress: mission profile variations.

- In this case, the SiC MOSFET is less thermally stressed than the Si IGBT.

Client | |

Project lead and execution: | |

Duration | 2 years |

Funding ggency (sponsor): | ECPE - European Center for Power Electronics |

Project team |