Decentralised production of green fuel from surplus algae oil

The cultivation of algae and the extraction of ingredients from them has become increasingly important in recent years. Algae carry out photosynthesis and are therefore a CO2 sink. However, they also contain valuable ingredients, such as omega-3 fatty acids, which are essential for nutrition. They also contain other «inferior» oils, from which fuels can be obtained. However, the production process required for this is a challenge, as the (large-scale) processes known to date are not adapted to the low growth rates of algae and the associated small quantities of oil.

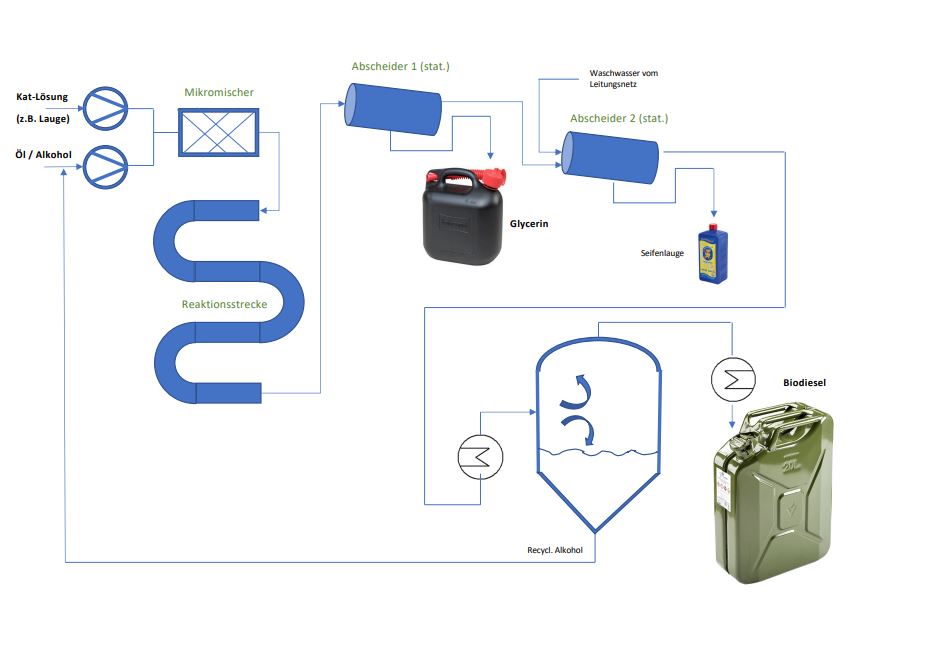

The «GREAT» project – “GReen Energy from Algae with microreactor Technology” – analysed ethanolic oil residues after extraction of high-quality «omega 3» fatty acids from microalgae (docosahexaenoic acid (DHA) and eicosapentaenoic acid (EPA)). The project investigated whether these residues can be converted into storable energy in the form of biodiesel, using a compact continuous process engineering system and the chemical process of «alcoholysis». This solution would enable on-site material flow processing in the microalgae farm and the resulting biodiesel could be used, for example, to power agricultural equipment. Batch laboratory tests using commercially available oils were conducted first to confirm the feasibility of converting oils from microalgae into biodiesel and glycerine with a yield of >80%, similar to that of other oils investigated (e.g. sunflower oil). The knowledge gained from the batch tests was then used to develop a continuous process. Although batch processing of microalgae oil waste is possible, it would lead to larger reactors and separation equipment, thus increasing procurement and operation costs. It would also be in conflict with the planned installation of the microalgae cultivation/oil extraction/waste utilization process on farms, as they often have little or no experience carrying out chemical reactions. A compact, continuous and ideally self-regulating plant, on the other hand, would not require such specialised knowledge. Microreactors were found to be the ideal flow and reaction technology solution. Not much larger than a pack of cards, they are compact continuous operation chemical reactors with low throughput rates and excellent mixing properties. It is known from alcoholysis that, given the poor to non-existent miscibility of alcohols with (vegetable) oils, an over stoichiometric addition of alcohol (up to 30:1 mol/mol) is necessary to achieve at least partial mixing of the reaction partners and thus obtain a sufficient yield. Of course the excess alcohol must then be removed, easily possible by means of distillation. However, additional thermal energy is needed for this removal, reducing the biodiesel production yield and increasing the CO2 footprint, since both the alcohol used and the thermal energy required currently still come mainly from fossil sources. This energy input can be significantly reduced if the immiscible reaction partners can be brought into intensive contact using efficient mixing technology, such as that provided by microreactors. Tests demonstrated the success of this approach: even with an alcohol:oil molar ratio of only 10:1, identical conversion rates could be achieved to those in the 40:1 laboratory batch test. Simultaneously, the reaction time required could be reduced by 90%, from 60 minutes in batch operation to less than 6 minutes with the continuous process. While surprising, this is critical for the process transfer from batch to continuous operation. With inline analysis devices such as density measurement (Coriolis measuring principle), the continuous process could also be effectively controlled and monitored – another key step for implementation in a compact, easy-to-operate process. Financial assessment of the overall process showed that it can be operated economically, and has advantages over a microalgae cultivation process lacking extraction of high-quality oils and biodiesel production.

Kommentare

Keine Kommentare erfasst zu Decentralised production of green fuel from surplus algae oil