3D-printed biodegradable metallic Mg scaffolds

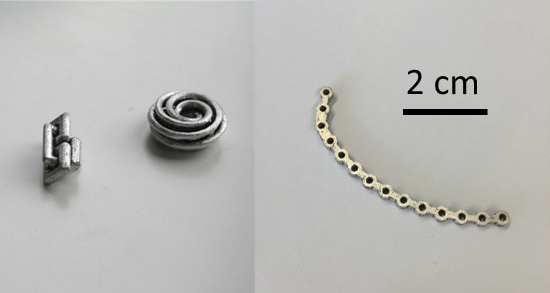

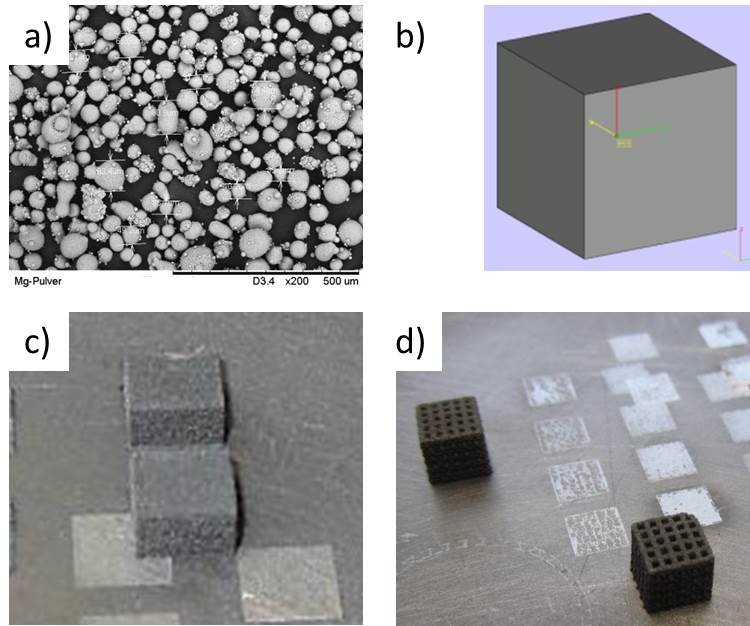

In this project, we show 3D-magnesium-structures produced by the additive manufacturing technology selective laser melting (SLM).

Due to the production flexibility this technology is already used to manufacture permanent, patient-specific, metallic implants made of cpTi. However, only a couple of SLM-Mg studies have been published at that time. Patient-specific, temporary solutions could be offered to the surgeon for the benefit of the patient.

The surgical application of permanent implants, e.g. osteosynthesis plates to stabilize fractured bones during healing, may be accompanied by disadvantages on the long-term, in particular when being placed in children or adolescent where impaired growth can result. Furthermore, implant dislocations, implant-associated infections or injuries of nerves and vessels can appear as side effects. Secondary surgeries to remove the implant after successful bone healing and to clinically eradicate this artificial foreign body often are expensive and complex. Resorbable implants, however, degenerate in-vivo, the foreign material is absorbed and no secondary surgery is necessary. Still, the mechanical strength of existing bioresorbable ceramic or polymeric biomaterials is too low for load-bearing applications. On the contrary, magnesium could be used as a biomaterial for the production of metallic, resorbable implants with sufficient mechanical properties.

- Safety recipient for controlled selective laser melting of magnesium

- Degradable Mg scaffolds produced by selective laser melting

- Customizing the microstructure in three-dimensional Mg structures

- Preliminary microstructural investigation of Mg cubes produced by SLM

- R. Marek, F. Wohlfender, B. Wiese, M. de Wild, Customizing the microstructure in three-dimensional Mg structures, proceeding of the 9th Biometal Symposium on Biodegradable Metals for Biomedical Applications, Met-4, 27. European Cells and Materials Meeting Abstracts 2017, Collection 4; Biometal 11 (2017).

- F. Wohlfender, N. Vogt, J. Rüegg, R. Marek, M. de Wild, Effect of process parameters on hardness of SLM-Mg material, Biomed Tech 2016 61, s30 (2016).

- J. Rüegg, S. Böhringer, A. Kessler, R. Schumacher, E. Schkommodau, M. de Wild, Degradable Mg scaffolds produced by selective laser melting, Front. Bioeng. Biotechnol. Conference Abstract: 10th World Biomaterials Congress, http://www.frontiersin.org/10.3389/conf.FBIOE.2016.01.00962/event_abstract.

- F. Wohlfender, S. Saxer, B. Wiese, J. Rüegg, A. Dietschy, R. Schumacher, M. de Wild, Preliminary microstructural investigation of Mg produced by SLM, European Cells and Materials 32. Suppl. 1, 24 (2016).

- S. Böhringer, A. Kessler, J. Rüegg, R. Schumacher, E. Schkommodau, M. de Wild, Safety recipient for controlled selective laser melting of magnesium, European Cells and Materials, 30; Suppl. 3, 4 (2015).