(Bio)mechanical Testing

(Bio)mechanische Prüfung neuartiger Implantatsysteme, chirurgischer Methoden und minimalinvasiver Behandlungen.

For the research, development and testing of novel implant systems, surgical methods and minimally invasive treatments, we carry out static and dynamic (bio)mechanical tests (tensile and compression testing at various temperatures, fatigue testing), removal-torque measurements and tests with complex, multi-axial load sequences. State-of-the-art motion analyzer using video extensometers, Digital Image Correlation and 3D navigation systems are available for the detection of trajectories and deformations.

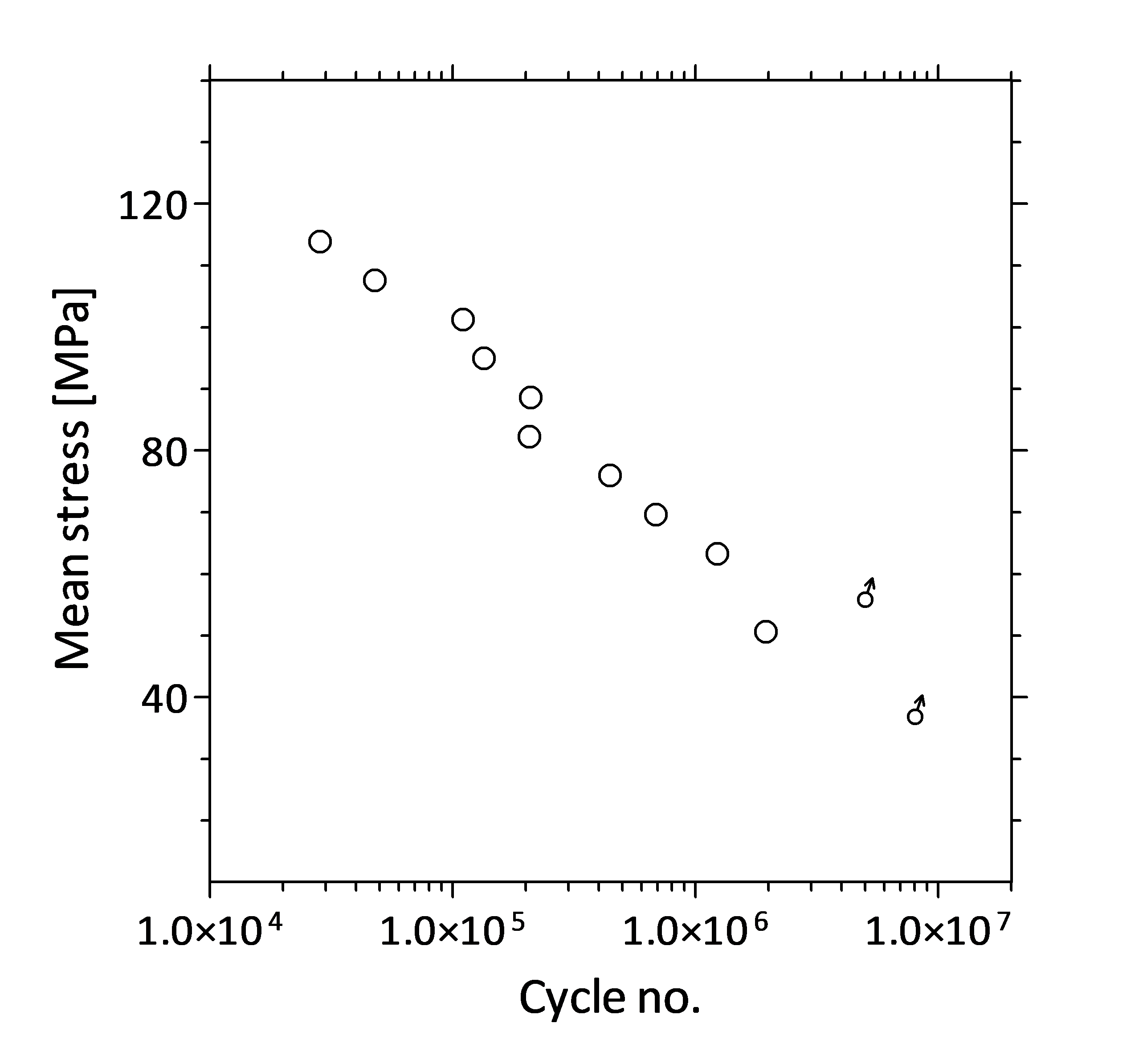

- Comparison of SLM and conventionally produced implants using dynamic biomechanical loading

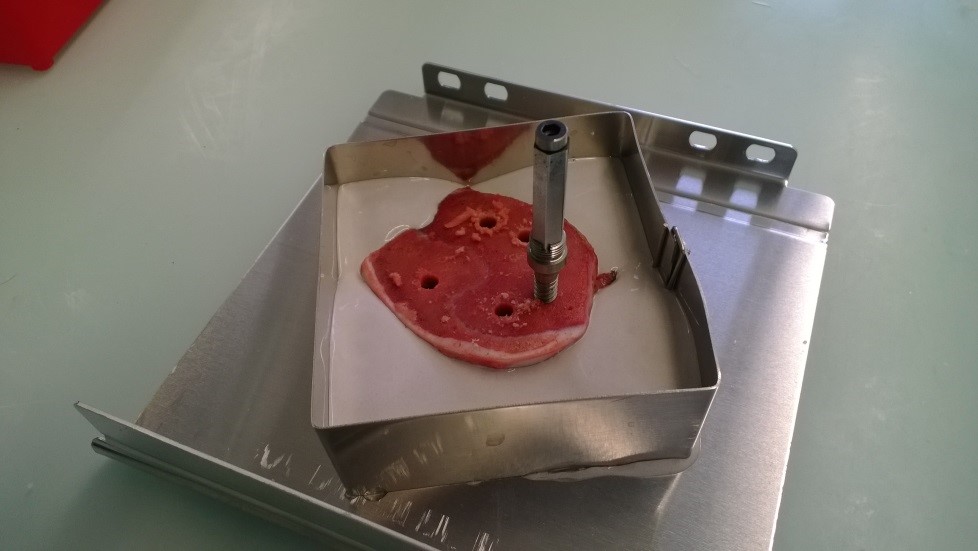

- Marker for the pre-clinical development of bone substitute materials

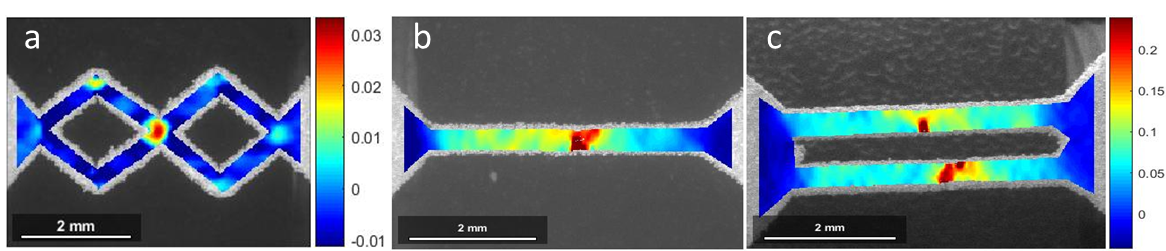

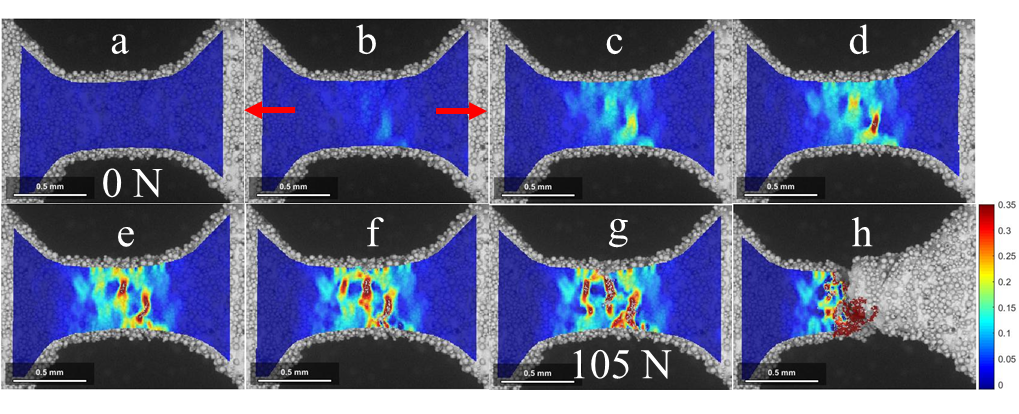

- In-situ fracture analysis of 3D-printed structures

- C.Rosso, T. Weber, A. Dietschy, M. de Wild, S. Müller, Three anchor concepts for rotator cuff repair in standardized physiological and osteoporotic bone: a biomechanical study, J Shoulder Elbow Surg. 2019 Oct 6. pii: S1058-2746(19)30529-4. doi: 10.1016/j.jse.2019.07.032.

- S. Müller, R. Flury, S. Zimmermann, M. de Wild, L. Lafosse, V. Bongiorno, C. Rosso, Superior Tissue Grip and Biomechanical Results - introducing the New LassoLoop360° Technique, doi 10.1007/s00167-019-05604-1, Knee Surgery, Sports Traumatology, Arthroscopy (2019).

- C. Rosso, S. Müller, D.M. Buckland, T. Schwenk, S. Zimmermann, M. de Wild, V. Valderrabano, All-inside Meniscal Repair Devices Compared to Their Matched Inside-Out Vertical Mattress Suture Repair: Introducing 10k and 100k Loading Cycles, Am J Sports Med. 42, 9; 2226-33 (2014).

- J. Sailer, N. Bless, F. Dalcanale, A. Stuemer, A. Dietschy, M. de Wild, A.M. Mueller, Development of a 3D biomechanical AC-joint model, 78. Jahrestagung SGOT Swissorthopaedics - Swiss Society of Orthopaedics and Traumatology, 6.-8. Juni 2018, Montreux (Switzerland).

- M. Meier, F. Schuler, M. de Wild, In-situ fracture analysis of 3D-printed structures, eCM Online Periodical, 2019, Collection 4; SSB+RM Conference Abstracts (page P2) (2019).

- M. de Wild, S. Zimmermann, M. Obrecht, M. Dard, Marker for the pre-clinical development of bone substitute materials, Current Directions in Biomedical Engineering 3(2): 711–715 (2017).

- R. Schumacher, M. de Wild, M. Ammann, A. Spiegel: Comparison of SLM and conventionally produced implants using dynamic biomechanical loading. Abstract RapidTech 2013, Erfurt (Germany).

- A. Spiegel, M. Roellinghoff, S. Fabbri, M. de Wild, Fatigue Strength of Medartis Adaptive Distal Radius Plate, American Academy of Orthopaedic Surgeons AAOS 2009 Annual Meeting, 25.-28.02.2009, Las Vegas, NV (USA).