Nanoporous Antibacterial Titanium Implants

A bacterial infection of an implant is painful and often requires a surgical replacement. Once the implant is covered with bacteria that produce a protective biofilm, a systemic treatment with antibiotics often is not successful. However, an antibacterial implant coating could be an effective preventive solution.

Our strategy: So far only a few antibacterial agents are in clinical use like e.g. the antibiotic gentamycin or silver in the form of nanoparticles immobilised to the surface of implants. Our strategy is using copper (Cu) as an antibacterial agent. It is known to show antibacterial properties and there are some advantage over antibiotics and silver: Cu has a low bacterial resistance building potential and no accumulation in the tissue is found. The final goal is to establish a stable and economical process to produce implant with a rough anodized surface where human bone cells attach well and grow fast but bacteria growth is suppressed.

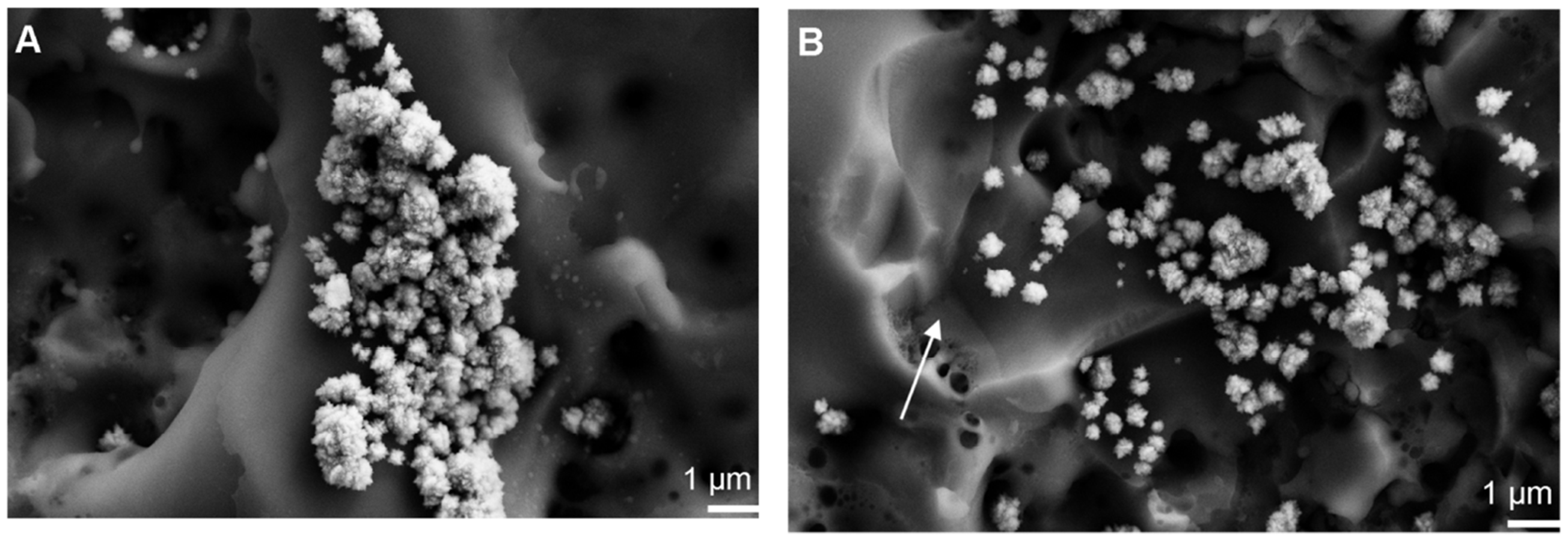

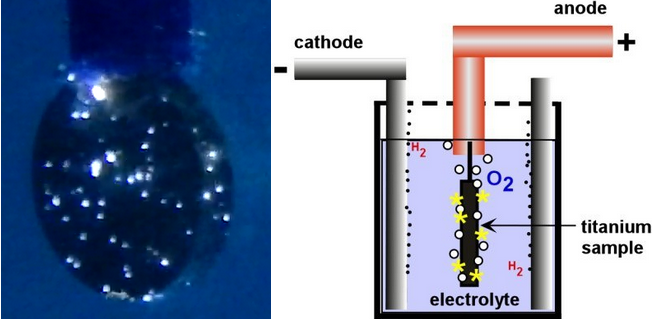

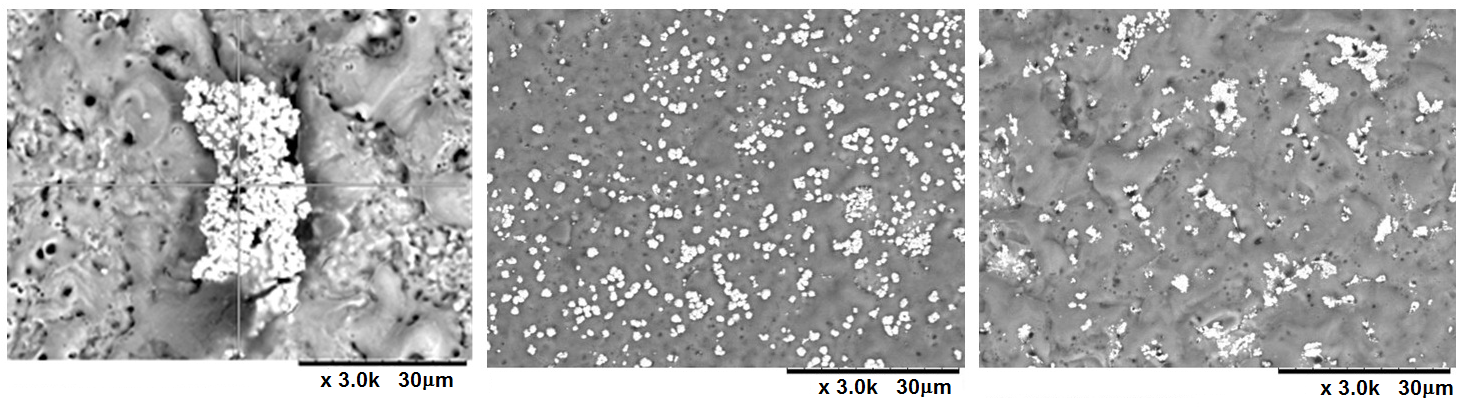

In order to deposit copper particles onto the implant surface in a controlled way, electrochemical deposition has been investigated. Ionic copper is added to an electrolyte and by applying an electrical current, the copper is deposited onto the implant. We are studying how the amount, homogeneity and particle size of the deposited Cu clusters are influenced by electrochemical parameters.

The oxide layer thickness, surface morphology, copper particle size distribution, adhesion of the deposits to the titanium substrate, release kinetics, biological response of bacteria and bone cells on such inorganically functionalized implants has been investigated.

- C. Jung, S. Mathes, E. Bono, C. Walker, A. Kessler, L. Straumann, M. de Wild, E.B. de Haller, Cell viability on titanium implant surfaces modified with antibacterial copper, European Cells and Materials, 29, Suppl. 2, 24 (2015).

- C. Jung, M. de Wild, Modifying titanium implant surfaces with antibacterial copper: Is this feasible? eCM XVI: Implant Infection, Davos (2015). European Cells and Materials Vol. 30. Suppl. 2, 54 (2015).

- C. Jung, L. Straumann, A. Kessler, U. Pieles, M. de Wild, Antibacterial copper deposited onto and into the oxide layer of titanium implants, BioNanoMat 15 (S1), S180, DOI 10.1515/bnm-2014-9017 (2014).

- L. Straumann, A. Kessler, U. Pieles, M. de Wild, C. Jung, Characterizing the mechanical stability of antibacterial copper deposits on anodized titanium implant surfaces, European Cells and Materials, 28, Suppl. 6, 21, ISSN 1473-2262 (2014).

- A. Kessler, L. Straumann, U. Pieles, M. de Wild, C. Jung, Release kinetics of electrochemically deposited antibacterial copper from anodized titanium implant surfaces, European Cells and Materials 27; 24, Suppl. 2 (2014).

- N. Ryter, J. Köser, W. Hoffmann, U. Pieles, C. Jung, F. Schlottig, M. de Wild, Antimicrobial Effects Of Titanium Surfaces With Incorporated Copper, Proceeding of the SSBE annual meeting, 22. August 2011 Bern, p. 12 (2011).

- W. Hoffmann, J. Köser, M. de Wild, I. Martin, F. Schlottig, C. Jung, U. Pieles, Antimicrobial Porous Surfaces for Ti implants, European Cells and Materials, 22, Suppl. 4, 20 (2011).

- L. Straumann, N. Balimann, F. Meier, M. de Wild und C. Jung, Effect of ultrasound on the electrochemical deposition of antibacterial copper particles at anodized titanium discs as model for titanium implants, European Cells and Materials, 26, Suppl. 1, 23 (2013).

- C. Jung, N. Ryter, J. Köser, W. Hoffmann, L. Straumann, N. Balimann, F. Meier, M. de Wild, F. Schlottig, U. Pieles, Antibacterial functionalization of the surface of titanium implants by electrochemical copper deposition. European Cells and Materials, 23, Suppl. 1, 16 (2012).

- KKS Ultraschall AG

- Antibacterial copper deposited onto and into the oxide layer of titanium implants

- European Cells and Materials Vol. 27. Suppl. 2, 2014

- European Cells and Materials Vol. 22. Suppl. 4, 2011

- European Cells and Materials Vol. 29. Suppl. 2, 2015

- European Cells and Materials Vol. 23. Suppl. 1, 2012

- Antibacterial functionalization of the surface of titanium implants by electrochemical copper deposition

- SMM 16/MSM 08 2010: Oberflächenveredelung von Medizinprodukten

- European Cells and Materials Vol. 30. Suppl. 2, 2015

- Antimicrobial effects of titanium surfaces with incorporated copper

- European Cells and Materials Vol. 28. Suppl. 6, 2014

- European Cells and Materials Vol. 26. Suppl. 1, 2013

- Smart NiTi constructs for 3D cell culture applications

- Properties of NiTi-structures fabricated by selective laser melting

KKS Ultraschall AG, Medical Surface Center, Christiane Jung, Steinen/Schwyz

Uwe Pieles, School of Life Sciences FHNW, Institute for Chemistry