SiC-MILE - SiC MedIum voLtage dEvices

The SiC-MILE project demonstrates Europe's first MV-SiC modules for energy savings in drives and traction.

Technologies

- SiC

- MV drives

- Railway

- Inverter

Bakground

Electric motors are the single most energy consuming systems of the planet, improvement in drive efficiency will significantly affect energy saving in Switzerland and worldwide. Particularly in Switzerland, the SiC MV drive technology can save up to 2.5% of the total energy consumed in the country.

Goals

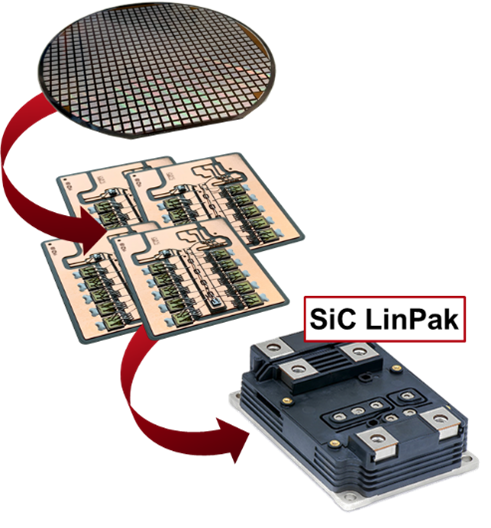

The project SiC-MILE will demonstrate the first MV SiC MOSFET packaging modules in Europe for industrial drives and traction systems. The demonstrators of this project comprises 3.3 and 6.5 kV SiC chips and modules fabricated in the Si semiconductor fab at Hitachi ABB power grids (HAPG) in Lenzburg AG as well as a 3.3 and a 6.5 kV MV 250 kW converters demonstrator built at the Fachhochschule Nordwestschweiz in Windisch.

These demonstrators will not only be the basis for the development of products targeting several millions of Swiss francs in annual exportations, but also be the technology platform enabler for the development of more energy efficient system applications in the national power electronics industry, thus becoming the first European supplier for the MV SiC power electronics industry.

Project information

Client | |

Execution | FHNW School of Engineering |

Duration | 2021 to 2024 |

Funding | |

Project lead | Prof. Dr. Renato Minamisawa |