Laser Applications Lab FHNW

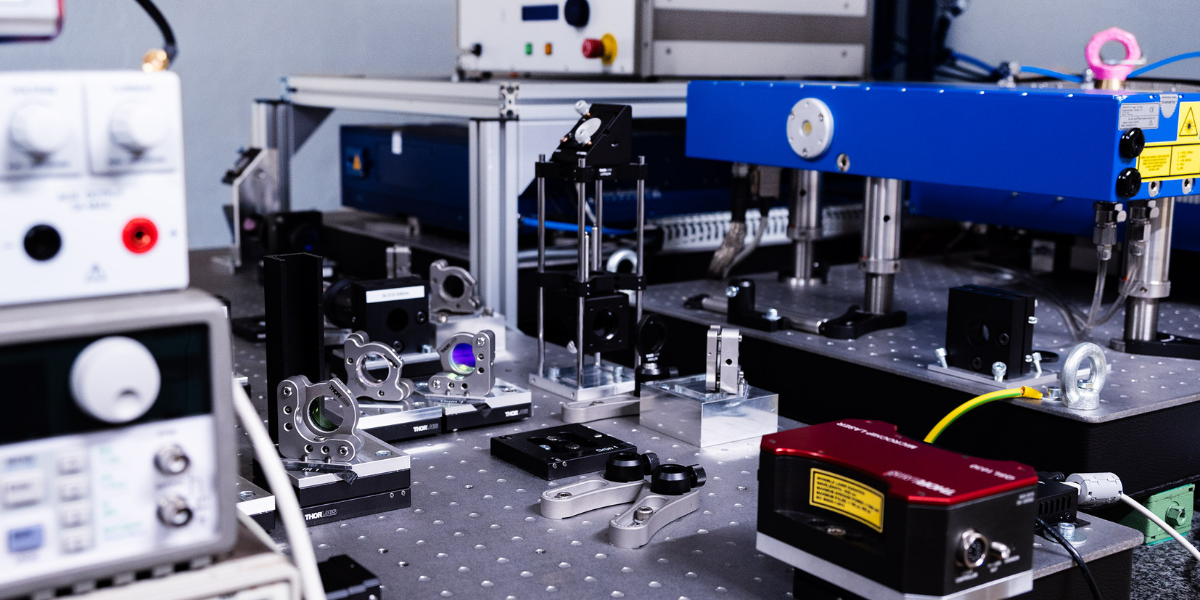

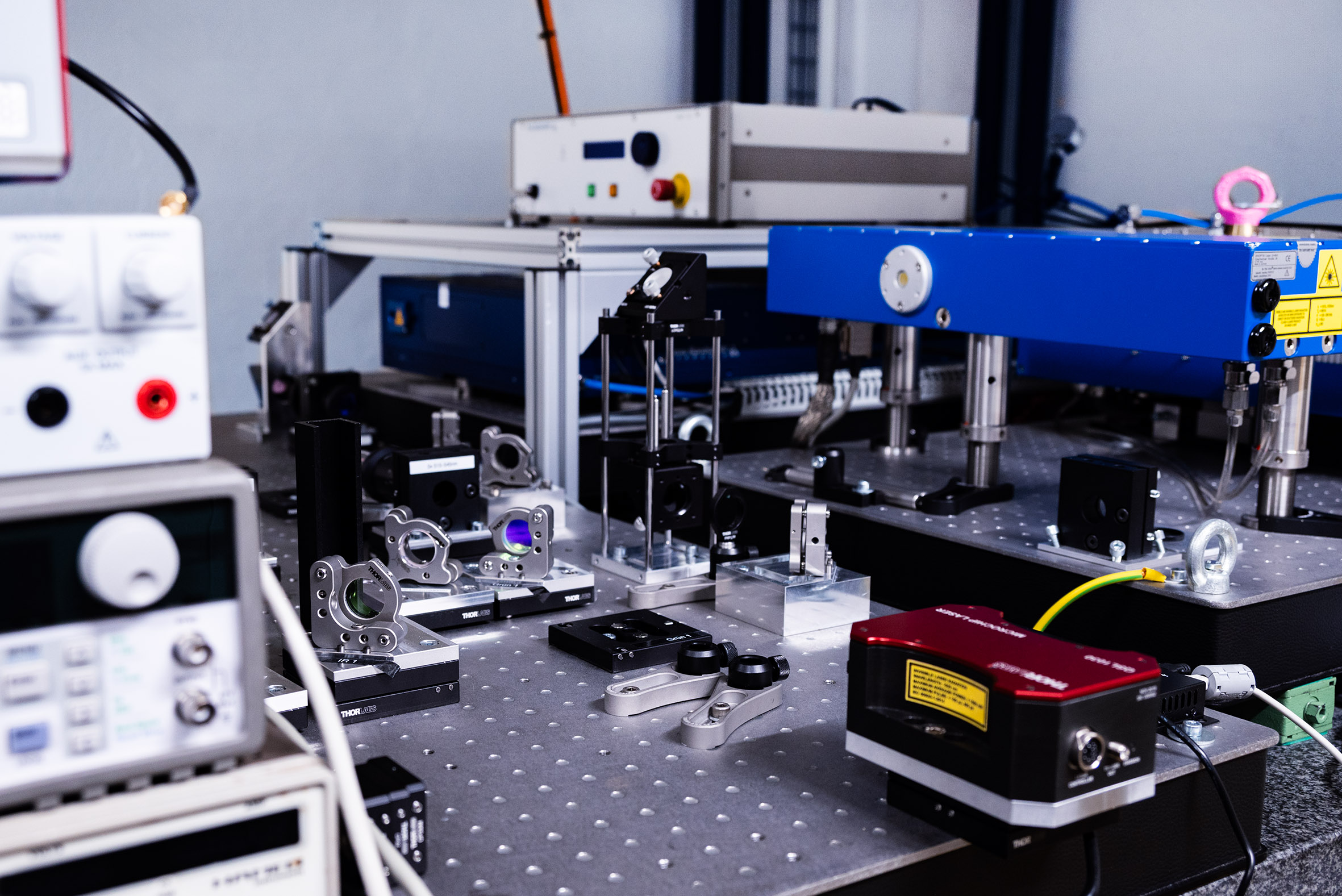

In our laboratory, we develop applications for 2.5D and 3D laser precision machining processes.

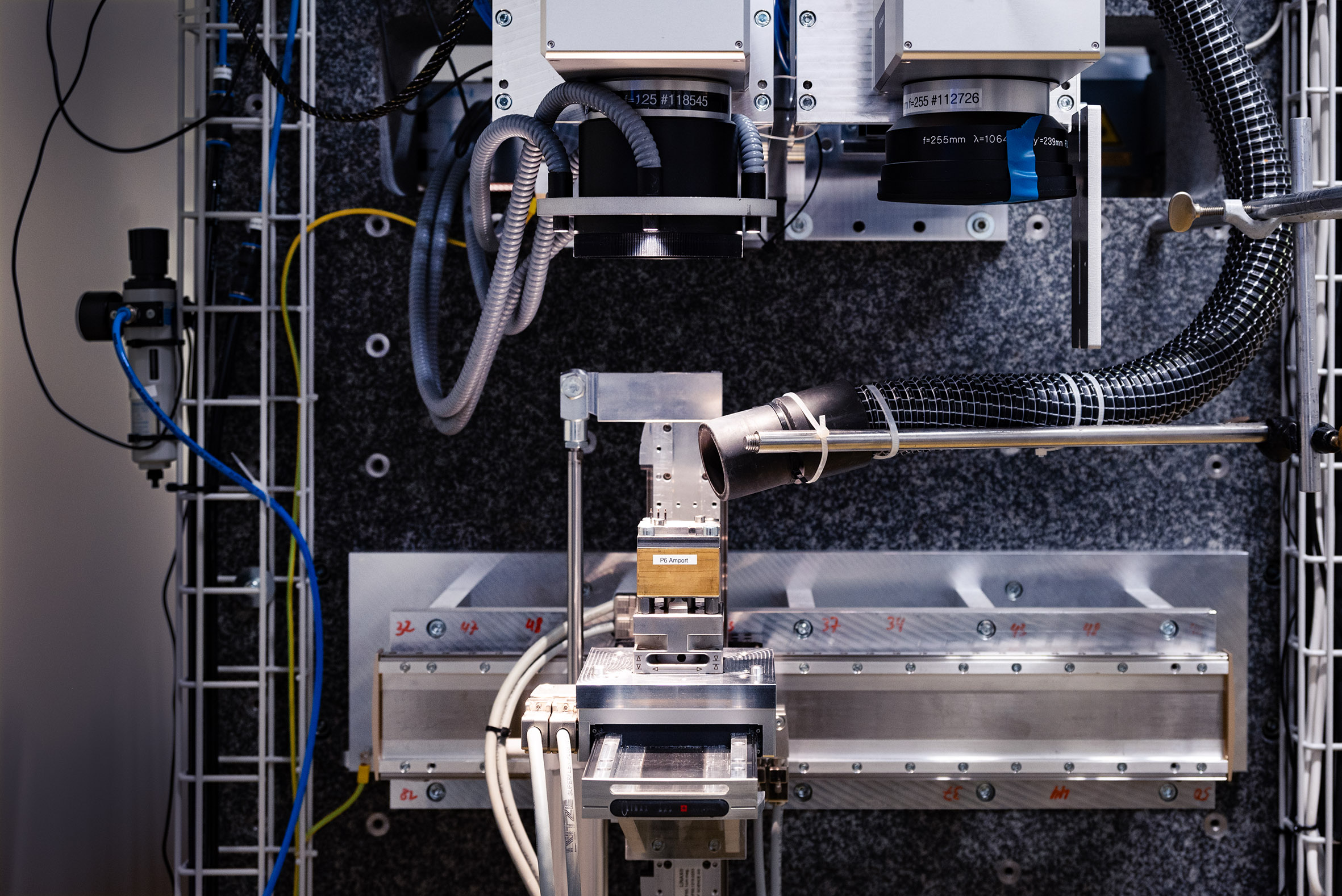

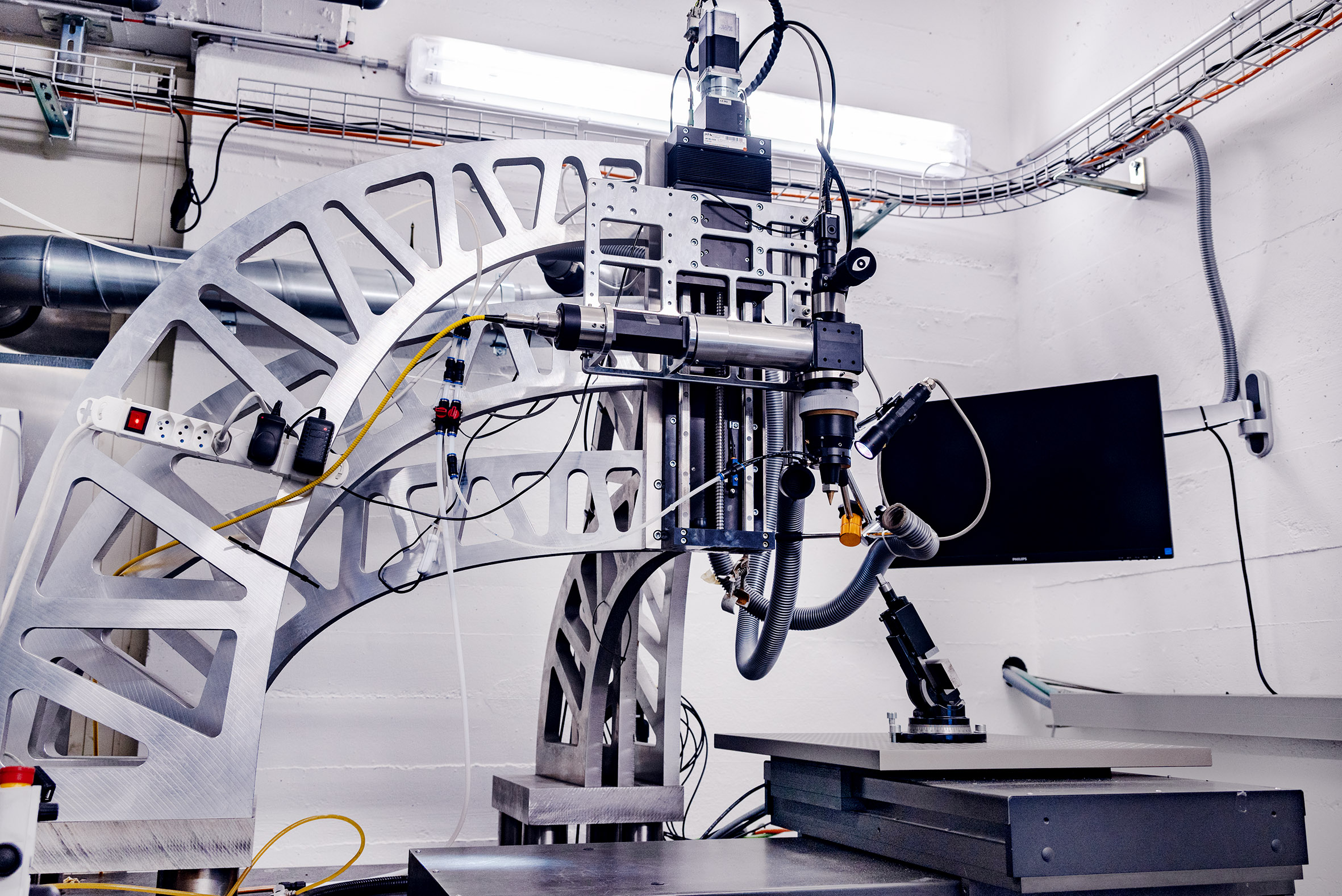

In the laboratory, we develop laser drilling, cutting and welding processes and test new beam guidance tools. A dynamic, high-precision 5-axis CNC precision laser system is available for these tasks. The available laser technology can be used to generate high-precision holes with high shaft ratios, as well as to weld conductive materials such as copper and aluminium alloys. Welding of nickel and cobalt-based alloys is also possible with the system technology.

The entire production process, from CAD to post-processing to the laser process, can be mapped for industrial processes.

The Precision Machining Laser Application Laboratory is one of the few training centres for laser applications such as laser welding, cutting and drilling in Switzerland.

For more information or to discuss a collaboration, please contact Ronald Holtz.

- CNC-controlled laser precision processing system (3 to 5 axes) with different laser sources and variable optical equipment, e.g. galvanometer scanner, high-speed rotary optics for "SHADOW" applications and variable direct beam working heads.

- 2 kW cw fiber laser

- 1.5 kW QCW fiber laser

- Video microscope for process monitoring

- Binocular and video microscope for process analyses