Porous shape-memory scaffolds as mechanically active bone implants

This project aims at realizing smart medical implants that interact with the surrounding bone tissue. Porous structures of the shape-memory alloy (SMA) Nickel-Titanium (NiTi) are created by additive manufacturing and tested in-vitro and in-vivo.

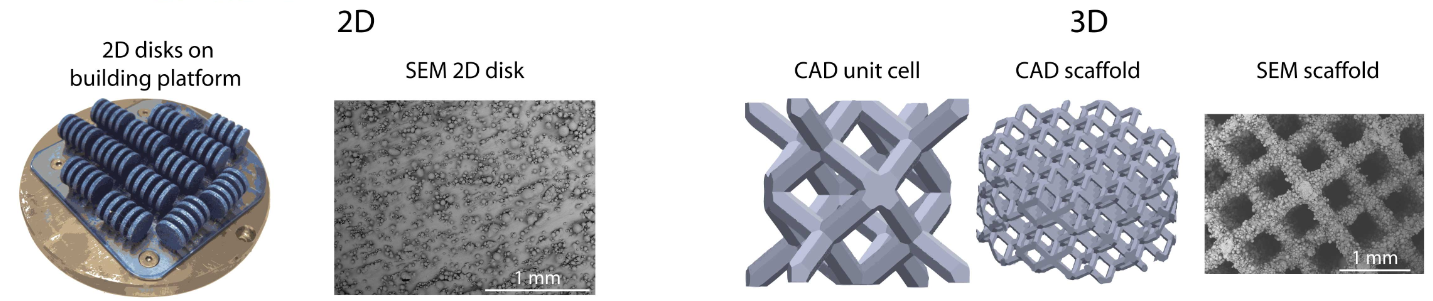

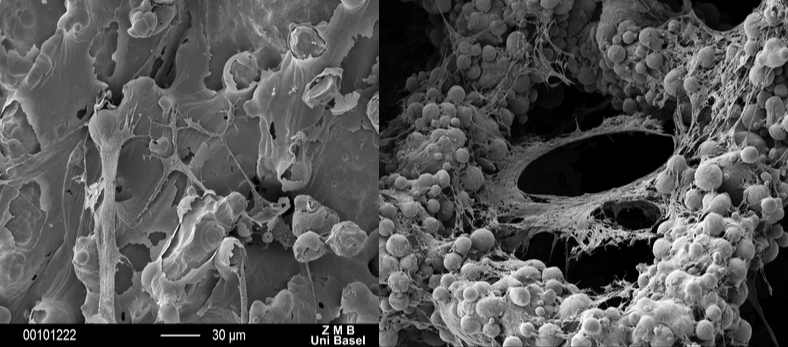

Using selective laser melting (SLM) we are fabricating SMA structures as scaffolds for Tissue Engineering applications and implants. The applied method allows the production of complex-shaped metallic structures based on a virtual CAD model. The interactions of the structures with progenitor cells as well as their response to three-dimensional structures are investigated within a novel bioreactor model system. This compression perfusion bioreactor serves as an in-vitro model for an orthotopic implantation site which allows for the testing of the NiTi scaffolds under physiological conditions.

The aim is the investigation of porous shape-memory structures as future implantable biomaterial with improved bone-tissue to implant interaction and therefore improved clinical outcome.

The damping properties of NiTi are associated with the martensite-austenite phase transformation. The results indicate that selective laser melting of NiTi is suitable for the fabrication of medical implants with ultra-high mechanical damping capacity.

The behaviour of the porous structures opens unknown perspectives and adaptations of the biofunctionality. The novelty of this technology lies in the fact that implantable structures can be produced with predefined physical and mechanical properties that can be optimized for specific functions in the body. In particular, the porous SMA structures can be associated with a better performance in bone tissue.

- T. Bormann, B. Müller, M. Schinhammer, A. Kessler, P. Thalmann, M. de Wild, Microstructure of selective laser melted nickel-titanium, Materials Characterization, 94, 189-202 (2014).

- W. Hoffmann, T. Bormann, A. Rossi, B. Müller, R. Schumacher, I. Martin, M. de Wild, D. Wendt, Rapid prototyped porous NiTi scaffolds as bone substitutes, J Tissue Engineering, 5; 1-14 (2014).

- W. Hoffmann, T. Bormann, A. Kessler, D. Wendt, M. de Wild, Ni release from rapid prototyped 3D NiTi scaffolds, European Cells and Materials, 28, Suppl. 6, 12, ISSN 1473-2262 (2014).

- T. Bormann, G. Schulz, H. Deyhle, F. Beckmann, M. de Wild, J. Küffer, C. Münch, W. Hoffmann, B. Müller, Combining micro computed tomography and three-dimensional registration to evaluate local strains in shape memory scaffolds, Acta Biomaterialia, 10, 1024-1034 (2014).

- T. Bormann, F. Beckmann, M. Schinhammer, H. Deyhle, M. de Wild, B. Müller, Assessing the grain structure of highly X-ray absorbing metallic alloys, International Journal of Materials Research 105;7, 692-701, doi 10.3139/146.111052 (2014).

- M. de Wild, F. Meier, T. Bormann, C.B.C. Howald, B. Müller, Damping of selective-laser-melted NiTi for medical implants, Journal of Materials Engineering and Performance, 23, 7; 2614-19 (2014).

- M. de Wild, T. Schollbach, R. Schumacher, E. Schkommodau, T. Bormann, Effects of laser parameters and scanning strategy on structural and mechanical properties of 3D NiTi implants fabricated with selective laser melting. poster, BMT 2013 Graz (Austria), September 2013. Biomed. Tech. 58, Suppl. 1 (2013) DOI 10.1515/bmt-2013-4088.

- T. Bormann, M. de Wild, F. Beckmann and B. Müller, Assessing the morphology of selective laser melted NiTi-scaffolds for a three-dimensional quantification of the one-way shape memory effect, Proc. SPIE. 8689, Behavior and Mechanics of Multifunctional Materials and Composites 2013 868914 1-8, DOI:10.1117/12.2012245 (April 3, 2013).

- W. Hoffmann, F. Schlottig, M. Mertmann, T. Bormann, I. Martin, D. Wendt, M. de Wild, Smart NiTi constructs for 3D cell culture applications, European Cells and Materials, 26, Suppl. 1, 22 (2013).

- W. Hoffmann, T. Bormann, F. Schlottig, M. Mertmann, R. Schumacher, U. Pieles, E. Schkommodau, B. Müller, D. Wendt, I. Martin, M. de Wild, The Interplay of NiTi shape memory alloys (SMA) and human Bone Marrow-Derived Mesenchymal Stromal Cells, Research Report 2011/2012, School of Life Sciences, University of Applied Sciences Northwestern Switzerland-FHNW, 40-41 (2012).

- T. Bormann, R. Schumacher, B. Müller, M. de Wild, Controlling Mechanical Properties of NiTi Scaffolds built by Selective Laser Melting, Biomed Tech 57 Suppl. 1, 568 (2012).

- T. Bormann, R. Schumacher, B. Müller, M. Mertmann, M. de Wild, Tailoring Selective Laser Melting Process Parameters for NiTi Implants, Journal of Materials Engineering and Performance, 21, 2519-2514 (2012).

- T. Bormann, F. Beckmann, M. de Wild, H. Deyhle, B. Müller, Preliminary Diffraction Contrast Tomography Study on NiTi fabricated by Selective Laser Melting, Annual Report DESY, Hamburg, 2012.

- T. Bormann, R. Schumacher, B. Müller and M. de Wild, From powder to complex-shaped NiTi structures by selective laser melting, European Powder Metallurgy Association, 16. -19.9.2012 Basel (Switzerland), Euro PM2012 Proceedings Volume 1, Applications and New Processes, p.193-197.

- T. Bormann, R. Schumacher, B. Müller, M. de Wild, Crystallographic phases of NiTi scaffolds fabricated by selective laser melting, European Cells and Materials, 22, Suppl. 4, 14 (2011).

- T. Bormann, R. Schumacher, B. Müller, M. de Wild, Fabricating NiTi shape memory scaffolds by selective laser melting, European Cells and Materials, 22, Suppl. 1, 12 (2011).

- T. Bormann, S. Friess, M. de Wild, R. Schumacher, G. Schulz, B. Müller, Determination of strain fields in porous shape memory alloys using micro computed tomography, Proc. of SPIE Vol. 7804 78041M-1-9 (2010).

- T. Bormann, R. Schumacher, B. Müller, M. Mertmann, U. Pieles, M. de Wild, Properties of NiTi-structures fabricated by selective laser melting, European Cells and Materials Journal, 20, Suppl. 1, 13 (2010).

- W. Hoffmann, S. Feliciano, I. Martin, M. de Wild, D. Wendt, Novel perfused compression bioreactor system as an in vitro model to investigate fracture healing, Frontiers in Bioengineering and Biotechnology, 3, 10:1-6 (2015).

- W. Hoffmann, C. Döbeli, R. Santoro, D. Wendt, M. de Wild, Reactor device for mechanical loading of tissue specimens and/or engineered tissues, European Patent Office Munich, priority application, EP 14/169756, 23 May 2014.

- From powder to complex-shaped NiTi structures by selective laser melting

- Fabricating NiTi shape memory scaffolds by selective laser melting

- Crystallographic phases of NiTi scaffolds fabricated by selective laser melting

- Fatigue behaviour of selective-laser-melted nickel-titanium scaffolds

- FEM analysis of porous titanium bone scaffold

- Ni release from rapid prototyped 3D NiTi scaffolds

- Smart NiTi constructs for 3D cell culture applications

- Properties of NiTi-structures fabricated by selective laser melting

SNF / KTI National Research Programme NRP-62 smart materials